CNC machined parts often have tight tolerances, sensitive surfaces, and complex geometries. Appropriate packaging is required to prevent scratches, impacts, corrosion, contamination, and dimensional changes from storage, handling, and transportation. This guide systematically compares common packaging solutions and provides practical configurations for different types of CNC components.

Core Requirements for CNC Machined Parts Packaging

Before comparing specific packaging solutions, it is necessary to clarify the protection objectives. Packaging for CNC machined parts typically needs to achieve the following:

- Maintain dimensional accuracy within specified tolerances

- Protect functional surfaces and edges from mechanical damage

- Prevent corrosion and surface discoloration

- Avoid contamination by dust, chips, oils, or moisture

- Facilitate traceability, identification, and batch management

- Support efficient handling, storage, and transportation

For many industrial users, the technical difficulty is not only selecting a single packaging material, but defining a complete system combining inner protection, physical support, moisture and corrosion control, and outer transport packaging.

Key Risks for CNC Machined Parts During Logistics

During internal plant transfer, warehousing, and external shipment, CNC machined parts may face multiple concurrent risks. Understanding these helps in selecting appropriate protective combinations for each process step.

Mechanical Damage and Impact

Common types of mechanical damage include:

- Surface scratches from part-to-part contact or contact with packaging walls

- Indentations caused by point loads or hard foreign bodies

- Deformation of thin-walled or long, slender parts due to stacking and compression

For parts with precision ground surfaces, mating faces, or sealing faces, even minor scratches or dents may cause rejection or additional rework.

Corrosion and Environmental Influences

Steel, cast iron, copper, and some aluminum alloys are sensitive to humidity, residual machining fluids, salts from sweat, and pollutants in the air. Typical corrosion issues include:

Visible red rust on carbon steel and cast iron, discoloration on alloy steels, and stain-like marks or pitting on aluminum and copper alloys. Condensation inside packaging is a frequent cause, especially in export shipments with varying temperature and humidity.

Contamination and Cleanliness Issues

Many CNC parts are delivered to subsequent processes such as assembly, coating, or heat treatment. Packaging must support required cleanliness levels by:

Preventing ingress of dust, fibers, and chips, avoiding lubricant or preservative leakage to other surfaces, and enabling clean-room or clean-area handling when specified.

Dimensional Stability and Deformation

Critical dimensions can be affected by residual stress, temperature shifts, or mechanical load during storage and transport. Packaging should avoid long-term bending loads on shafts or plates, prevent localized pressures on precision surfaces, and allow stable stacking without overloading lower layers.

Selection of Inner Packaging Materials

Inner packaging is in direct contact with the parts and is responsible for primary protection. Selecting suitable materials depends on part geometry, material, and surface requirements.

| Material Type | Main Functions | Typical Applications | Key Advantages | Important Limitations |

|---|---|---|---|---|

| PE bags (flat or gusseted) | Dust protection, basic moisture barrier | General metal parts, non-precision surfaces | Low cost, wide availability, easy sealing | Limited mechanical protection, no active anti-corrosion |

| VCI bags and VCI films | Corrosion inhibition and moisture protection | Steel, iron, and mixed metal parts, export packaging | Provides volatile corrosion inhibitors, convenient to use | Requires tight enclosure; performance depends on film quality and volume ratio |

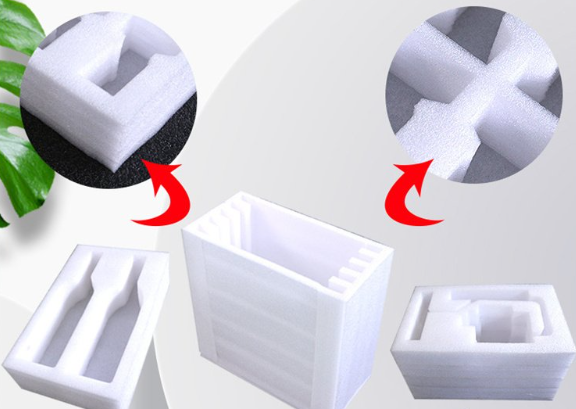

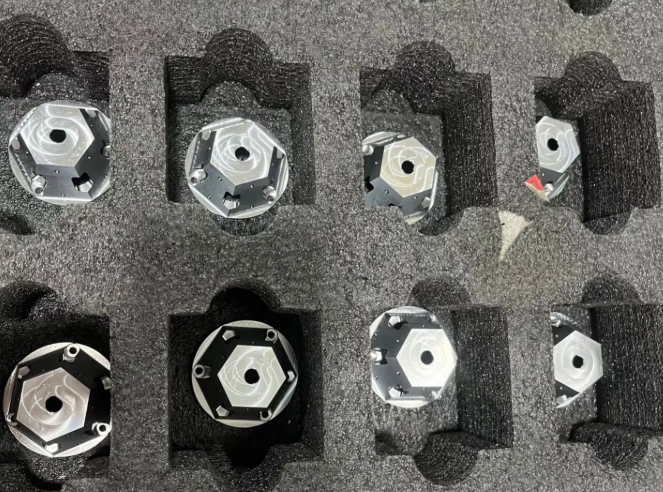

| Foam inserts (EPE, PU, EVA) | Shock absorption, cushioning, fixation | High-value parts, precision surfaces, fragile geometries | Customizable cavities, good vibration damping | Higher unit cost, may require tooling for complex shapes |

| Bubble wrap | Surface protection and shock absorption | General machined components, assemblies | Flexible and simple wrapping, good for small series | Limited shape stability, not suitable for heavy parts without extra support |

| Paper wrap and interleaving sheets | Surface isolation, scratch prevention | Stacked parts, plated or painted surfaces | Low cost, good for separating layers | Limited moisture resistance; must avoid direct contact with oily surfaces if paper is not treated |

| VCI paper | Corrosion protection and surface separation | Tools, gears, rings, and flat components | Combines rust prevention with mechanical separation | Effectiveness depends on enclosed space; not sufficient for heavily contaminated parts |

| Thermoformed trays (plastic) | Positioning, part-to-part isolation | Serial production parts with stable geometry, small to medium size | Repeatable positioning, suitable for automated handling | Requires design and tooling; less flexible for frequent part changes |

Protective Films and Bags

Simple PE bags are suitable when parts are relatively robust and the focus is on cleanliness and basic moisture protection. Thickness selection typically ranges from 40 to 100 microns depending on size and weight.

VCI bags and films add corrosion protection. For effective use, parts should be clean and dry, the volume of air within the package should be limited, and the packaging should remain closed for the required protection duration. Film thickness commonly ranges from 60 to 120 microns for heavy or sharp-edged parts to reduce puncture risk.

Foam and Cushioning Materials

Foam is often employed when the part has sensitive surfaces, protruding features, or high value. Key parameters include density, compression strength, and rebound characteristics. For medium-weight metal parts, EPE foam in densities of 25 to 35 kg/m³ is frequently used, while higher densities or EVA foams are applied where higher compression resistance is required.

Trays, Partitions, and Inserts

Thermoformed trays and corrugated partitions allow high packing density while preventing part-to-part contact. The layout must consider the outer packaging dimensions, stacking pattern, and handling method. For precise positioning, cavity dimensions should account for tolerances in both part and tray manufacturing, as well as foreseeable dimensional changes in temperature and humidity.

Outer Packaging and Transport Units

Outer packaging ensures mechanical integrity, stackability, and protection from external environmental conditions during storage and transport.

| Outer Packaging Type | Typical Construction | Suitable Use Cases | Advantages | Considerations |

|---|---|---|---|---|

| Corrugated cartons | Single, double, or triple wall corrugated board | Small to medium parts, domestic shipping | Cost-effective, lightweight, easy printing | Limited resistance to high humidity and heavy loads, requires pallets for long distances |

| Wooden crates | Plywood or solid wood panels with wood framing | Export shipments, large parts, heavy assemblies | High strength and stackability, good protection | Higher cost and weight; may require ISPM 15 compliance |

| Returnable plastic bins | Rigid HDPE or PP containers | Internal logistics, closed-loop supply chains | Durable, consistent dimensions, suitable for automation | Investment cost, system requires reverse logistics |

| Metal containers | Steel frameworks and side panels | Very heavy parts, automotive and heavy industry | High load capacity, long service life | High acquisition cost, more complex handling |

Corrugated Cartons

Corrugated cartons are common for small and medium CNC parts. Critical parameters include board grade, wall construction, and stacking test strength. For heavy machined components, double wall or triple wall boards with appropriate edge crush strength should be selected. Carton design should consider internal dunnage and reinforcements around hand holes and corners.

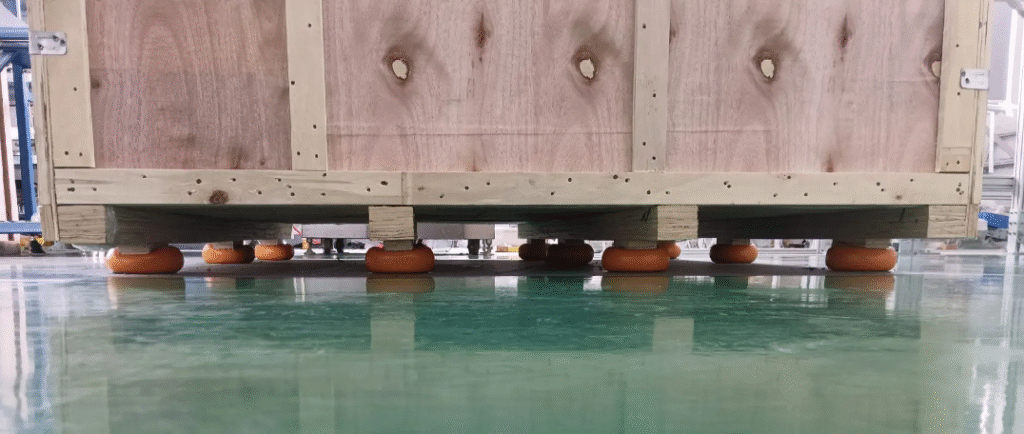

Wooden Crates and Boxes

Wooden packaging offers robust protection and is often used for export or for large parts. Typical design elements include skid or pallet bases, side and top panels, internal blocking to prevent movement, and optional vapor barrier liners. For international shipments, solid wood components may require treatment and marking according to ISPM 15 regulations.

Returnable and Reusable Containers

Returnable plastic or metal containers are suitable for long-term supply relationships with stable part mixes. The internal packaging (trays, inserts, foam) is usually designed to fit these containers. This approach provides consistent protection and handling efficiency, particularly in automotive and machinery supply chains.

Corrosion Protection Strategies for Metal CNC Parts

Corrosion prevention is essential, especially for ferrous metals and mixed metal assemblies. Packaging should integrate suitable preservation methods and materials.

Temporary Corrosion Protection Methods

Common methods include oil-based rust preventives, water-based or solvent-based corrosion inhibitors, VCI technologies, and desiccant-based drying. Oil-based protectives offer long-lasting protection but may require cleaning before assembly. Water-based products facilitate easier removal and are more suitable when low residual film is required.

Use of VCI Products

VCI products, such as films, bags, and papers, release corrosion inhibitors that form a molecular layer on metal surfaces. For CNC machined parts, they are useful when:

- Parts are cleaned and dried before packaging

- Package is tightly sealed to maintain concentration of inhibitors

- Protection duration and environmental conditions are known

For mixed metals, VCI products formulated for multi-metal protection should be used. It is important to avoid unnecessary venting of the package and to limit opening and closing cycles during intermediate storage.

Desiccants and Moisture Barriers

Desiccants reduce humidity in a closed environment by adsorption. They are typically used in combination with barrier materials, such as aluminum-laminated foil bags or high-barrier PE films. For CNC parts, desiccants are especially useful in long-distance sea shipments and in climate zones with high humidity. Calculation of required desiccant quantity should consider internal volume, packaging material permeability, and planned storage duration.

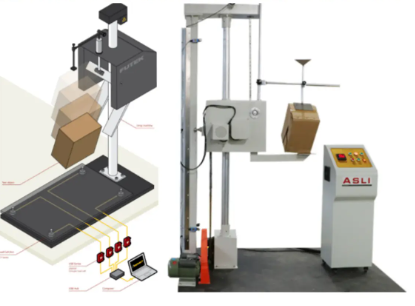

Impact Protection, Fixation, and Load Management

Besides corrosion control, the structural design of packaging is critical for protecting CNC parts against impact and vibration.

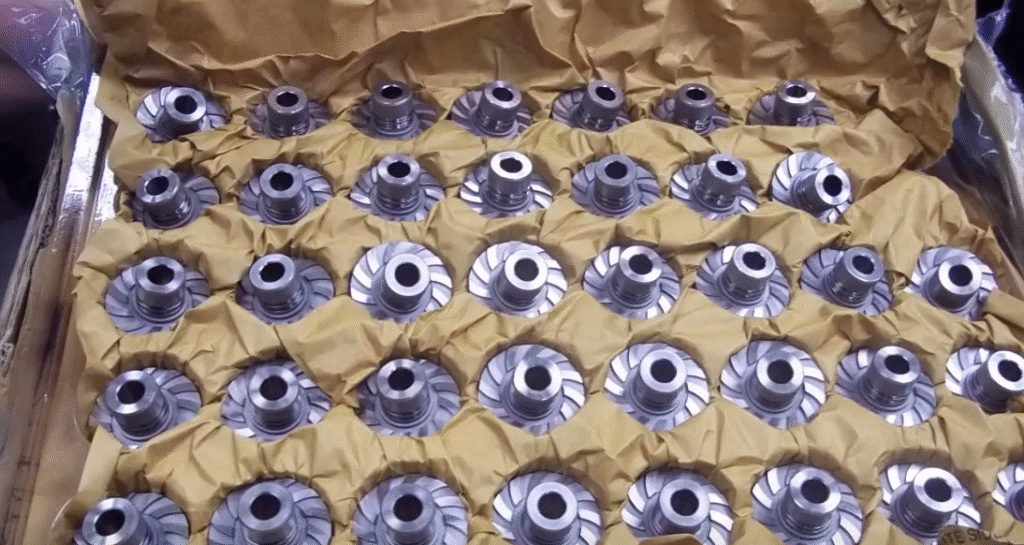

Individual vs. Group Packing

Individual packing prevents contact between parts and is suitable for delicate or high-value components. It often involves foam cavities, thermoformed trays, or individual wrapped units. Group packing allows several parts per compartment and is appropriate when surfaces are less critical, or when separated by interlayers or partitions. The chosen strategy should match the allowable cosmetic and functional defect levels.

Shock Absorption and Vibration Damping

For transport exposure, shock absorption layers, corner protectors, and cushioning should be tuned to the mass of the parts and expected acceleration levels. Overly soft materials may allow excessive movement, while materials that are too rigid transmit shock to the parts. For stacked containers, the packaging configuration should ensure even load distribution and avoid point loads that may distort precision surfaces.

Stacking Strength and Unitization

Stacking strength depends on outer packaging, pallet quality, and stacking pattern. For CNC machined parts, excessive stacking can cause distortion of parts at the bottom or crushing of internal dunnage. Guidelines include limiting stacking height based on carton or crate compression resistance, using top frames or covers to improve load distribution, and applying strapping or stretch wrapping to stabilize pallet units.

Packaging Solutions by Part Type and Geometry

Different CNC machined components have distinct packaging needs. Tailoring solutions to part geometry and function improves reliability and efficiency.

Shafts, Pins, and Long Slender Parts

These parts are susceptible to bending and surface damage along their length. Typical solutions include:

Using plastic or cardboard tubes for individual or grouped shafts with end caps to prevent axial movement, employing foam strips or profiles that support the shaft at multiple points, and arranging longitudinal parts horizontally in crates with separators to distribute load and avoid point contact.

Flat Plates, Flanges, and Rings

Flat parts often have machined faces that must remain free of scratches and warping. Solutions typically include interleaving protective sheets or VCI paper between parts when stacking, using trays with recesses that match the outer geometry, and limiting stack height and using rigid boards to spread load evenly across surfaces.

Complex Housings, Blocks, and Brackets

These parts may have protruding features, threaded holes, and sealing surfaces. Suitable packaging configurations often involve custom foam inserts or thermoformed trays for repeatable positioning, local protection of critical surfaces and threads with caps or plugs, and cavity orientation that avoids trapping residual coolant or condensate.

Precision Surfaces and Optical or Sealing Faces

Where parts contain ground, lapped, or polished surfaces, packaging must prevent any contact that could mark these areas. Measures include the use of non-abrasive films or soft foam layers directly over sensitive surfaces, separating contact surfaces with dedicated protective covers or caps, and minimizing manual handling by using trays compatible with automated or semi-automated handling equipment.

Cleanliness and Contamination Control

CNC machined parts are frequently used in assemblies with elevated cleanliness requirements, such as hydraulic systems, automotive drivetrains, or aerospace mechanisms.

Clean Packaging Environments

For parts with defined cleanliness classes, the packaging area may need to be controlled for particles and humidity. Packaging materials should be low-lint and compatible with required cleaning processes. Using clean PE bags and sealed trays, limiting open time between cleaning and sealing, and separating dirty and clean zones within the workshop are common practices.

Control of Residual Coolants and Oils

Residual processing media can interact with packaging materials, desiccants, or corrosion inhibitors. To ensure predictable performance, cleaning and drying procedures should be standardized, including specified cleaning agents and rinsing methods, controlled drying conditions and time before packaging, and defined maximum time between cleaning and sealing the packaging to avoid flash rust on sensitive metals.

Identification, Traceability, and Documentation

Accurate identification of CNC machined parts and their packaging units is crucial for quality control and logistics management.

Labels and Markings

Labels should be resistant to abrasion and moisture, readable throughout the handling cycle, and placed on multiple sides of outer packaging if necessary. Typical label data includes part number, description, and revision, quantity and packaging unit identification, batch or lot number, date of packaging, and preservation method used, such as type of VCI or oil.

Documentation Inside and Outside the Package

Certain shipments, especially export consignments, may require internal packing lists or inspection records. These can be:

Placed in document pouches on the outside of crates or pallets, sealed inside transparent bags within the outer packaging when required by the customer, and integrated with barcodes or QR codes to link to digital documentation, such as certificates, measurement reports, or special instructions.

Packaging Configuration Examples

Practical combinations of materials and methods allow engineers to select appropriate solutions more quickly. The following typical configurations illustrate how inner and outer packaging can be combined.

Medium Size Steel Flanges for Export

A typical configuration could include cleaned and dried flanges with residual protective oil, stacking with VCI paper between each flange, wrapping stack in VCI film or placing in VCI bag with seal, and loading wrapped stacks into a wooden crate with foam padding on bottom and sides. Desiccants can be added in high humidity environments, and the crate closed with screws and appropriately marked.

Aluminum Housings for Serial Supply to OEM

For repeated deliveries in a closed supply chain, a configuration might use sealed, cleaned housings placed in custom thermoformed trays, trays stacked within returnable plastic bins with internal spacers to avoid compression, and bins labeled with durable barcodes. Outer wrapping on pallet can use stretch film with corner protection to maintain unit stability.

Long Steel Shafts for Road Transport

Effective packaging may use light oil coating on shaft surface, fitting plastic protectors on both ends and keyways, placing shafts in individual cardboard or plastic tubes where quantity per tube and tube strength match shaft weight, and grouping multiple tubes in a wooden crate with internal blocking to prevent axial sliding.

Quality Control and Verification of Packaging Performance

Packaging for CNC machined parts should be validated as part of the quality management system. Verification typically includes inspection of packed parts after test transport, checking for scratches, corrosion, deformation, or contamination, simulated stacking or compression tests to confirm structural adequacy, and review of sealing integrity for VCI or moisture barrier packaging after defined time intervals.

Sampling and Periodic Review

Packaging performance may change over time due to material changes, new logistics routes, or environmental conditions. It is advisable to:

Conduct periodic sampling of received parts at the customer site, monitor frequency and types of damage claims related to packaging, and adjust materials or methods when process or product changes occur. Documented packaging specifications should be maintained and updated as necessary.

Cost and Efficiency Considerations in Packaging Design

Packaging must balance protection performance with cost and operational efficiency. For CNC machining businesses, packaging design affects total delivered cost, not just material expenses.

Material Cost vs. Damage Cost

While higher performance materials may increase unit packaging cost, they frequently reduce damage rates and rework, which often outweighs material savings. Quantifying the cost of scrap, rework, and customer claims attributable to packaging failures can guide rational selection.

Handling Efficiency and Ergonomics

Packaging configurations should support efficient operation by being compatible with standard pallets and containers, suitable for mechanical handling when required, and manageable by operators, limiting the need for awkward lifting or complex unpacking processes. Reducing redundant layers and steps without compromising protection improves productivity and consistency.

FAQ: Protective Packaging for CNC Machined Parts

Why is protective packaging important for CNC machined parts?

CNC machined parts often have precise tolerances and delicate surfaces. Proper packaging prevents scratches, dents, corrosion, and contamination during storage or transportation, ensuring the parts arrive in perfect condition.

Are there packaging solutions for irregularly shaped parts?

Yes. Custom foam inserts, molded trays, or individually designed boxes can securely hold irregular or complex-shaped parts, preventing movement and impact during transit.

What is the recommended procedure for packaging high-precision parts?

Clean and dry the parts thoroughly.

Apply protective films or anti-corrosion coatings if needed.

Place parts in foam or molded trays to avoid contact with each other.

Wrap trays in bubble wrap or anti-static materials.

Seal in a sturdy box with cushioning to prevent movement.

Do CNC parts always need desiccants in export packaging?

Desiccants are not always mandatory, but they are strongly recommended for sensitive metals when shipping across climate zones or by sea, where humidity and temperature can fluctuate significantly. When using high-barrier liners or foil bags with long storage times, desiccants help control internal humidity. If proper VCI products are used and storage times are moderate, desiccants may be optional, but risk assessment based on destination, transit time, and material sensitivity is necessary.

How do you prevent corrosion during shipping?

Corrosion can be prevented using rust-inhibiting paper, desiccant packs, vacuum sealing, or applying protective coatings like oil or wax, depending on the part material.