CNC technologies are widely used in modern production, but the terms “CNC manufacturing” and “CNC machining” are often used interchangeably. In practice, they describe different scopes of activity. Understanding the distinction is important for project planning, supplier selection, quoting, and quality control.

CNC Machining: Definition, Scope and Core Principles

CNC machining is a subtractive manufacturing process in which computer numerical control (CNC) equipment removes material from a workpiece to form a final geometry. It is a process-level term, focused on the actual material cutting and shaping operation.

Core Characteristics of CNC Machining

- Subtractive: Starts with stock (bar, plate, block, casting, forging) and removes material.

- Numerically controlled: Tool paths and motions are defined by G-code executed by the CNC controller.

- Repeatable and precise: Consistent part geometry across multiple cycles, with defined tolerances.

- Flexible: Suitable for prototypes, small batches, and production runs across many materials.

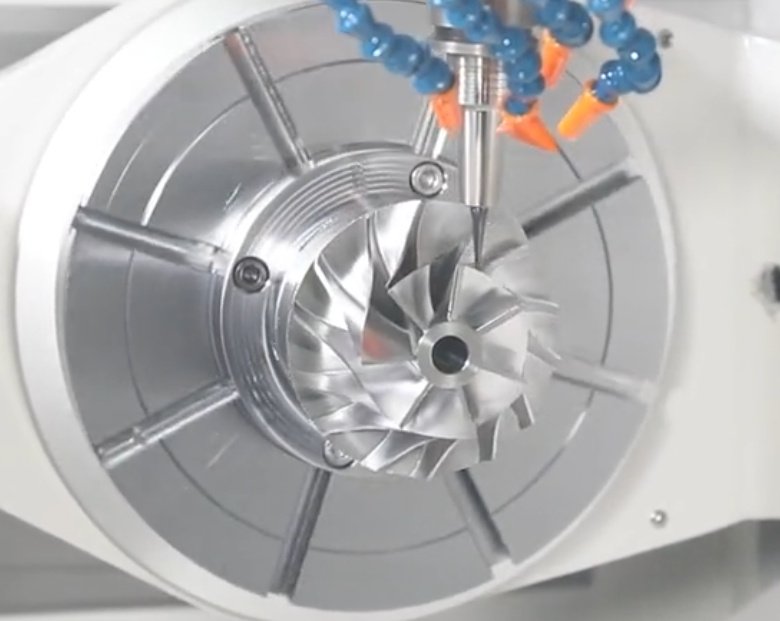

Typical CNC machining operations include milling, turning, drilling, tapping, boring, reaming, and various contouring and profiling operations. These may be performed on separate machines or combined on multi-axis machining centers and turn-mill machines.

Key CNC Machining Processes

CNC machining includes several specific process types, each optimized for particular part geometries and throughput requirements.

CNC milling uses rotating cutting tools and typically a stationary or indexed workpiece. It is used to produce prismatic shapes, pockets, slots, contours, and complex 3D surfaces.

CNC turning uses a rotating workpiece and stationary or moving cutting tools to generate cylindrical, conical, and threaded surfaces. Turn-mill centers may integrate milling and drilling operations in the same setup.

Additional machining operations can be integrated into milling or turning centers or performed on dedicated machines. These include drilling, tapping, boring, reaming, and thread milling.

Technical Parameters in CNC Machining

CNC machining is characterized by measurable technical parameters that influence dimensional accuracy, surface quality, and productivity. Key parameters include spindle speed, feed rate, depth of cut, tool type, coolant strategy, and workholding method.

| Parameter | Common Range | Influence on Process |

|---|---|---|

| Spindle speed (milling) | 500–24,000 rpm (general-purpose); up to 40,000+ rpm (high-speed) | Impacts surface finish, tool life, thermal load, chip formation |

| Feed rate (milling) | 100–10,000 mm/min (material and tool dependent) | Affects cycle time, surface finish, cutting forces |

| Depth of cut (axial/radial) | 0.1–10 mm or more, depending on tool and rigidity | Determines material removal rate and cutting forces |

| Dimensional tolerance | ±0.010–0.050 mm typical; down to ±0.002–0.005 mm with fine machining | Defines precision level and affects process planning |

| Surface roughness (Ra) | 0.4–3.2 μm typical; down to 0.2 μm or better with finishing | Impacts functional performance and appearance |

These ranges depend strongly on machine rigidity, tooling technology, material, coolant, and fixturing. For every part, parameters are optimized for the required tolerance, surface quality, and cost target.

CNC Manufacturing: Definition, Scope and System Perspective

CNC manufacturing is a broader, system-level concept. It includes CNC machining as one of several operations, but also covers all associated processes required to deliver finished parts or assemblies using CNC as the core technology.

In practice, CNC manufacturing encompasses the complete workflow from design input to inspected, packaged, and possibly assembled products. It is a production strategy that uses CNC machines and related systems to produce components with defined quality, cost, and lead time targets.

Elements Typically Included in CNC Manufacturing

CNC manufacturing environments frequently include the following activities and resources:

- Design and engineering support for DFM (Design for Manufacturability) and process selection.

- CAM programming, toolpath optimization, and simulation.

- Tooling and fixture design and fabrication.

- Material sourcing, traceability, and stock management.

- CNC machining, turning, milling, drilling, and related operations.

- Post-machining operations (deburring, finishing, coating, assembly).

- Inspection, measurement, documentation, and certification.

- Production planning, scheduling, and quality management systems.

CNC manufacturing therefore integrates CNC machining machines into a wider production ecosystem, often alongside other processes such as additive manufacturing, sheet metal fabrication, or casting, depending on the factory layout.

System-Level Characteristics of CNC Manufacturing

From a system perspective, CNC manufacturing focuses on throughput, repeatability across batches, traceability, and compliance with industry standards or customer requirements. It uses standardized workflows, documentation, and quality tools to maintain consistency.

Typical aspects include structured routing, work instructions, tool management databases, maintenance schedules, and process capability monitoring. Production is often organized by part families, machine type, or product cells to optimize material flow and machine utilization.

Conceptual Difference: CNC Machining vs CNC Manufacturing

The core distinction lies in scope: CNC machining refers to the machining process itself, while CNC manufacturing refers to the entire production chain that uses CNC as a central technology.

CNC machining is usually described at the operation or workstation level. It deals directly with cutting conditions, tool geometry, workholding, and NC programs. CNC manufacturing is described at the factory or supply-chain level. It integrates process planning, logistics, quality, and business aspects.

| Aspect | CNC Machining | CNC Manufacturing |

|---|---|---|

| Scope | Specific subtractive process on a CNC machine | End-to-end production system using CNC technologies |

| Focus | Toolpaths, cutting parameters, machine operation | Workflow, logistics, quality, capacity, and output |

| Typical deliverable | Individually machined part or feature | Finished part or assembly, inspected and documented |

| Included activities | Cutting, drilling, turning, milling, etc. | Design support, CAM, machining, finishing, inspection, packaging |

| Usual users of the term | Manufacturing engineers, programmers, machinists | Operations managers, buyers, project managers, OEMs |

| Time horizon | Single setup or operation cycle | Entire project lifecycle and multiple production batches |

In purchasing and technical communication, recognizing this difference helps set accurate expectations. A “CNC machining service” may focus on producing parts from provided drawings with basic inspection. A “CNC manufacturing partner” typically delivers broader support, including process planning, documentation, and extended services.

Typical Workflow for CNC Machining Operations

At the level of a single CNC machining operation or sequence, the workflow is focused on transforming a raw workpiece into a defined geometry within targeted tolerances and surface characteristics.

Design Interpretation and Process Planning

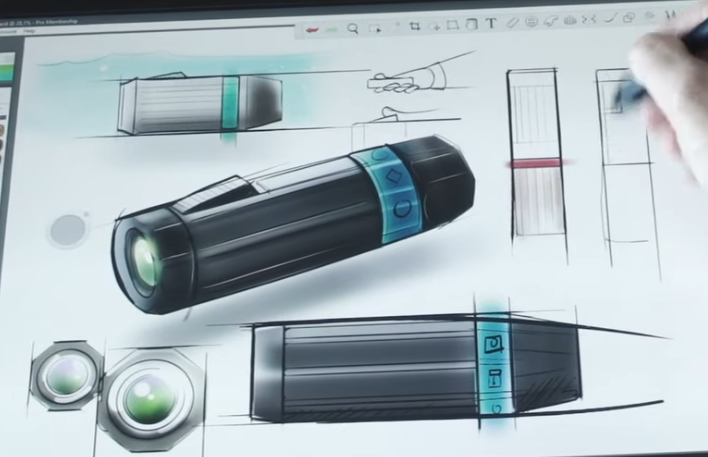

The workflow usually begins with a 2D drawing and/or 3D CAD model. The machinist or manufacturing engineer interprets:

- Critical dimensions and tolerances.

- Geometric dimensioning and tolerancing (GD&T) requirements.

- Surface finish symbols and notes.

- Material type and condition.

- Any special requirements such as burr limits or edge breaks.

Base stock size and type are selected, process steps are defined, and the sequence of operations and needed setups is determined. For complex parts, multiple machines or fixtures may be required.

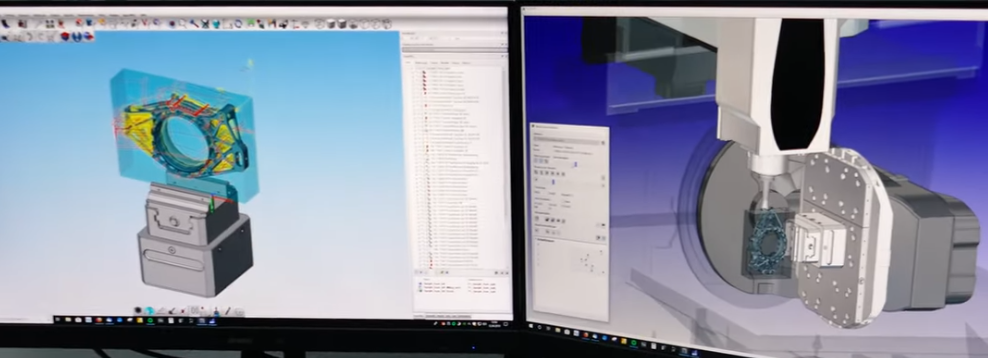

CAM Programming and Simulation

CAM software is used to create toolpaths, define cutting strategies, and generate G-code. Steps include:

Tool selection based on geometry, material, and desired surface quality; definition of speeds, feeds, and depths of cut; selection of toolpath strategies; use of stock models and verification; collision checks and machine simulation; and post-processing to match the target CNC control.

The resulting NC program is typically transferred to the CNC machine via DNC, network, or portable media.

Setup, Proving, and Production Runs

On the machine, the operator mounts and aligns fixtures, loads tools into the tool changer, sets tool lengths and diameters, establishes work coordinate systems, and performs dry runs or single-block runs to verify the program.

Once validated, production runs proceed with in-process checks, tool wear monitoring, and adjustments as needed. First-article inspection may be performed before full production release.

Typical Workflow for CNC Manufacturing at System Level

At the manufacturing system level, the workflow includes all steps from initial technical communication to shipment. The purpose is to consistently deliver parts within specification and within the required timeframe.

Inquiry, Quotation, and DFM Review

When a customer submits a request, the CNC manufacturing supplier reviews drawings, CAD data, and requirements such as material, quantities, and inspection level. A DFM review may highlight machinability, tolerance stack-up, and cost drivers. The quotation reflects material cost, machining time, setup effort, finishing, inspection, overhead, and logistical considerations.

Production Planning and Scheduling

Once the order is confirmed, the manufacturing team creates routing through the shop. The plan defines required operations, machines, setups, fixtures, and inspections. It also assigns due dates and integrates the new work into existing schedules, considering machine capacity, tool availability, and material lead times.

Integrated Operations and Quality Control

During execution, CNC manufacturing includes incoming material inspection where required, machining and intermediate inspections, post-processing such as heat treatment, finishing or coating, final inspection using defined measurement methods, and packaging or assembly.

Documentation often includes inspection reports, certificates of conformity, material certificates, and traceability records. In many applications, process parameters and inspection results are archived for future reference and continuous improvement.

Materials and Part Types Commonly Used

CNC machining and CNC manufacturing work across a wide range of materials. Material selection is driven by functional requirements such as strength, corrosion resistance, thermal properties, and cost.

Metals

Common metallic materials include aluminum alloys (e.g., 6061, 6082, 7075), steels (carbon steels, alloy steels, tool steels), stainless steels (e.g., 304, 316, 17-4PH), copper and copper alloys, and titanium alloys (e.g., Ti-6Al-4V). Each material requires specific cutting data and tool choices to achieve consistent results.

Plastics and Composites

Engineering plastics such as POM, PA, PEEK, PC, and PVC are frequently machined. They are often used in prototypes, low-volume components, and insulating parts. Composite machining may involve carbon-fiber-reinforced polymer (CFRP) or glass-fiber-reinforced materials, where cutter selection and cutting parameters are optimized to minimize delamination and fiber pull-out.

Typical Parts and Features

CNC machining is used for housings and enclosures, shafts and pins, brackets and mounts, manifolds and blocks, molds and dies, precision components with tight dimensional and geometric tolerances, and functional prototypes that must match production materials.

Dimensional Accuracy, Tolerances, and Surface Quality

CNC machining and CNC manufacturing share the same basic capability envelope for accuracy and surface finish, but manufacturing systems ensure that these capabilities are repeatable across batches and time.

Dimensional Tolerance Capabilities

Typical tolerance capabilities depend on machine tool quality, environment, and process control. For general-purpose milling and turning, tolerances of ±0.050 mm are common. With controlled processes and stable conditions, tolerances down to ±0.010 mm or tighter are achievable, and in high-precision environments ±0.002–0.005 mm can be reached on specific features.

In CNC manufacturing, tolerances are also connected with process capability indices (Cp, Cpk), which quantify how consistently a process produces within tolerance over time. This is essential for series production and critical components.

Surface Roughness

Surface roughness (Ra) is defined by tool geometry, material, feeds and speeds, and finishing passes. Typical milling surface roughness is in the range of 0.8–3.2 μm Ra for standard passes. Finishing steps and optimized parameter sets can produce 0.4 μm Ra or better on many metals. Turning can provide similar or finer finishes, especially with dedicated finishing inserts and stable conditions.

Where very low roughness values are required, CNC machining may be followed by grinding, lapping, or polishing. In CNC manufacturing environments, these additional processes are integrated into the routing and inspection plan.

Production Volume, Lead Time, and Cost Considerations

From an economic viewpoint, the difference between CNC machining and CNC manufacturing becomes important when estimating costs and planning production volumes.

Suitability by Volume

CNC machining is well suited for one-off prototypes, engineering samples, custom fixtures, and low-volume production. Setup costs are usually moderate, and unit cost is mainly driven by machining time and material usage.

CNC manufacturing covers a wider volume range, from one-off components to repeated series production. For recurring work, investments in dedicated fixtures, standardized setups, and optimized toolpaths decrease unit cost over time and improve consistency.

Lead Time Elements

Lead time for CNC machining is influenced by material availability, programming and setup time, and machine capacity at the moment of scheduling. For CNC manufacturing, additional factors such as finishing, heat treatment, inspection capacity, documentation requirements, and shipping add to the overall lead time.

In practice, the difference is that a local CNC machining service may supply a prototype quickly, while a CNC manufacturing partner manages full project lead times including all auxiliary steps.

Typical Issues and How Scope Affects Them

Users often encounter certain issues when working with CNC suppliers. Understanding the difference between machining and manufacturing scope helps in addressing these points more effectively.

Dimensional Consistency Across Batches

For isolated CNC machining jobs, dimensional consistency is achieved through machine accuracy and operator skill. In CNC manufacturing, consistency is reinforced by formal process control, documented work instructions, and statistical monitoring.

When repeated orders show dimension shifts or variability, the underlying issue is often process definition and control, not the machining operation alone. A manufacturing-oriented approach helps stabilize results by defining and maintaining process parameters systematically.

Handling Multiple Operations and Subcontracted Processes

Many parts require several steps beyond CNC machining, such as heat treatment, surface coating, or assembly. When these are managed separately by the customer, logistical complexity and quality risk increase.

CNC manufacturing integrates these steps into a single controlled workflow, with responsibility for coordination and verification assigned to the manufacturing supplier. This reduces handling and miscommunication and centralizes accountability.

How to Choose Between CNC Machining and CNC Manufacturing Services

From a buyer’s viewpoint, the choice is not between two different technologies, but between two levels of service scope.

When a CNC Machining Service is Sufficient

A machining-focused service is usually appropriate when the requirement is limited to producing parts from a drawing or model, post-processing is minimal or handled in-house, volumes are modest, and documentation requirements are simple.

In this case, emphasis is placed on machine capability, programmer and operator skills, and responsiveness.

When a CNC Manufacturing Partner is More Appropriate

A manufacturing-level partner is more suitable when multiple operations and suppliers need to be coordinated, consistent quality over many batches is critical, formal documentation and traceability are required, or design support and DFM feedback are valuable.

In these situations, the capability to plan and control the entire process chain, rather than only the machining operation, is a key factor in project success.

FAQ: CNC Manufacturing vs CNC Machining

What is the main difference between CNC manufacturing and CNC machining?

CNC machining refers specifically to the subtractive cutting and shaping process on CNC machine tools, such as milling and turning. CNC manufacturing is a broader term that includes CNC machining but also covers process planning, material sourcing, tooling, finishing, inspection, and logistics required to deliver finished parts or assemblies.

When should I look for a CNC machining service instead of a CNC manufacturing provider?

A CNC machining service is suitable when you need parts made from your drawings or models, volumes are low or moderate, and you handle additional steps such as coating, assembly, or extended documentation yourself. If you require an integrated solution that includes multiple processes, quality documentation, and long-term production support, a CNC manufacturing provider is more appropriate.

Is CNC machining a part of CNC manufacturing?

Yes. CNC machining is one of the core processes within CNC manufacturing. While CNC manufacturing may involve multiple automated methods, CNC machining focuses on shaping materials by removing material.

Which is better: CNC manufacturing or CNC machining?

Neither is “better”—they serve different scopes.

Choose CNC machining when you need precise subtractive operations on metals or plastics.

Choose CNC manufacturing when your project requires a combination of processes (e.g., machining + bending + welding + finishing).

When should I choose CNC machining over other CNC manufacturing methods?

Choose CNC machining if you need:

High precision and tight tolerances

Complex 3D geometries

Smooth surface finish

Prototyping with quick turnaround

For high-volume or multi-step production, CNC manufacturing processes may be better.