Computer Numerical Control (CNC) machines are at the core of modern manufacturing, providing repeatable accuracy, high productivity, and reliable quality for metal, plastics, composites, and other materials. Understanding the main types of CNC machines helps engineers, machinists, and production managers choose appropriate equipment, optimize machining processes, and control costs.

This guide explains the 5 main types of CNC machines in detail, focusing on operating principles, structure, axes configuration, typical specifications, and typical industrial applications.

CNC Milling Machines

CNC milling machines remove material by rotating a cutting tool against a stationary or moving workpiece. They are among the most widely used CNC machine types for producing prismatic and complex 3D parts with high dimensional accuracy.

Working Principle of CNC Milling

CNC milling is a subtractive manufacturing process in which a rotating multi-point cutting tool moves along programmed paths (toolpaths) to remove chips from the workpiece. The CNC controller interprets G-code and controls:

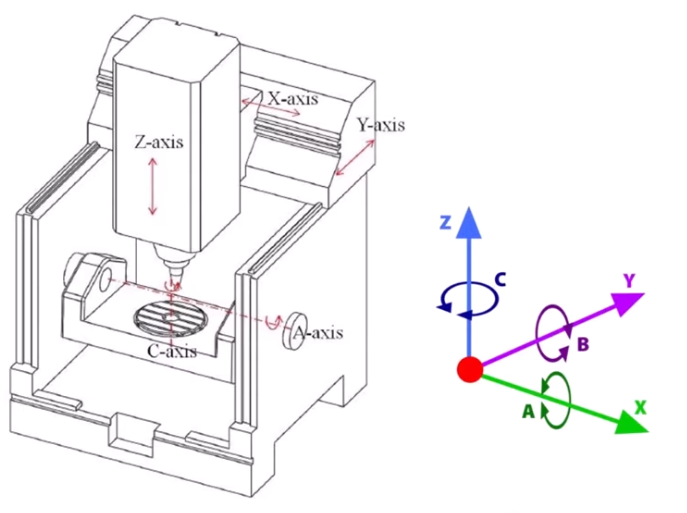

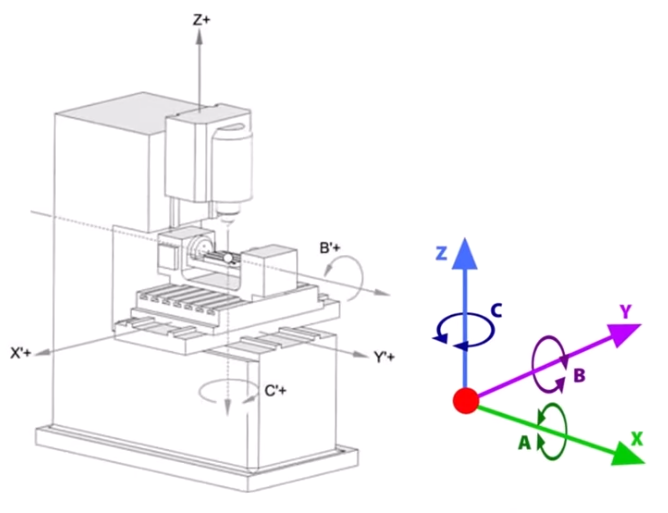

- Linear motion along X, Y, Z axes

- Rotational or tilting motion along additional rotary axes (A, B, C) on multi-axis machines

- Spindle speed, feed rate, coolant flow, tool changes, and probing cycles

The tool engages the workpiece in various milling operations such as facing, slotting, pocketing, contouring, drilling, tapping, and 3D surface machining.

Main Types of CNC Milling Machines

Common configurations of CNC milling machines include:

- Vertical Machining Center (VMC): Spindle is oriented vertically; widely used for 2.5D and 3D machining, molds, and general parts.

- Horizontal Machining Center (HMC): Spindle oriented horizontally, often equipped with pallet changers; better for chip evacuation and production machining.

- Gantry / Bridge Mill: Large frame with a moving crossbeam; suitable for large workpieces, molds, dies, and aerospace structures.

Typical Axis Configurations and Capabilities

Axis count significantly affects complexity and flexibility:

| Machine Type | Common Axes | Typical Use | Complexity Level |

|---|---|---|---|

| 3-axis VMC/HMC | X, Y, Z | 2D profiles, pockets, standard prismatic parts | Basic |

| 4-axis (indexing or continuous) | X, Y, Z + A or B | Parts with features on multiple faces, simple impellers | Intermediate |

| 5-axis simultaneous | X, Y, Z + A + B or C | Complex 3D surfaces, aerospace, medical implants | Advanced |

Key Specifications

Important parameters when evaluating a CNC milling machine include:

- Travel range: X, Y, Z strokes (e.g., 800 × 500 × 500 mm)

- Spindle speed: typical 6,000–15,000 rpm; high-speed options up to 30,000 rpm

- Spindle taper: BT30/40/50, HSK, CAT, etc.

- Rapid traverse and feed rates: e.g., rapid 30–60 m/min, cutting feed up to 10–20 m/min depending on material

- Tool magazine capacity: 16–120 tools or more

- Positioning accuracy and repeatability: typically ±0.005–0.01 mm for standard VMCs

Common Applications of CNC Milling

CNC milling is used in:

Automotive industry for engine blocks, transmission housings, brackets, and fixtures. Aerospace for structural components, turbine blades (on 5-axis), and precision fittings. Mold and die making for injection molds, stamping dies, and die-casting molds, especially requiring high surface finish and accuracy. General engineering for mechanical parts, jigs, fixtures, and production tooling.

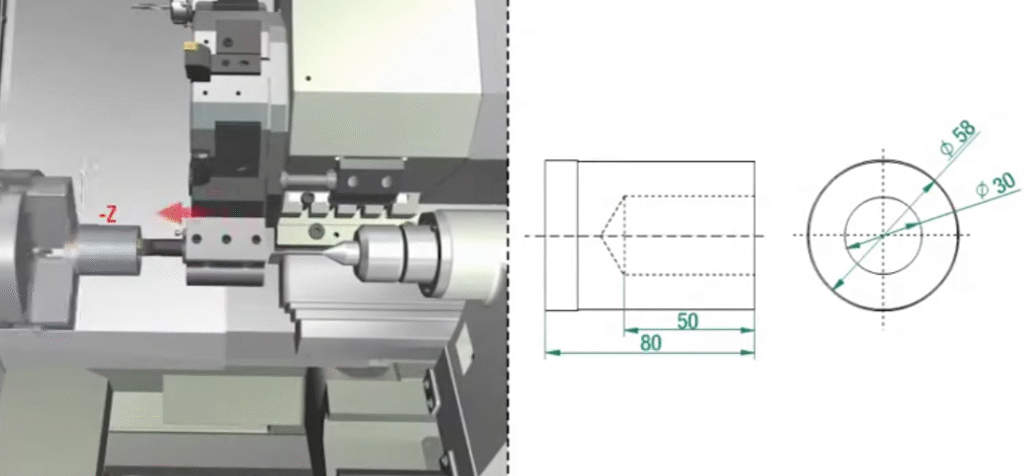

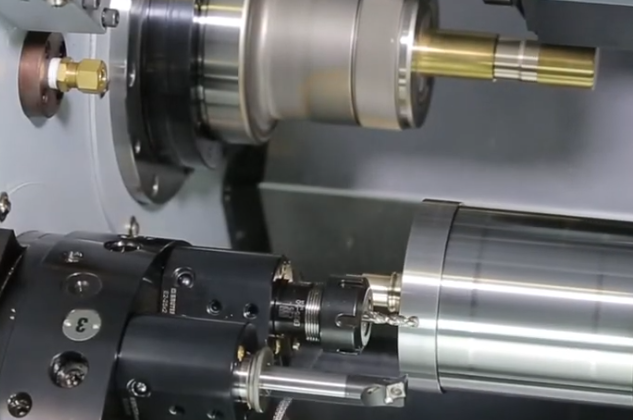

CNC Lathes and Turning Centers

CNC lathes and turning centers are used to produce rotational or axisymmetric parts by rotating the workpiece against a stationary or moving single-point cutting tool. They are fundamental for shafts, bushings, fasteners, and many precision cylindrical components.

Working Principle of CNC Turning

In CNC turning, the workpiece is clamped in a chuck or collet and rotated around the spindle axis. Cutting tools mounted on a turret or tool post move along linear axes (typically X and Z). Material is removed in the form of chips according to programmed toolpaths.

Most CNC lathes perform operations such as facing, external and internal turning, grooving, drilling, boring, and threading. Advanced turning centers integrate milling and drilling (C-axis or Y-axis) to complete multiple operations in one setup.

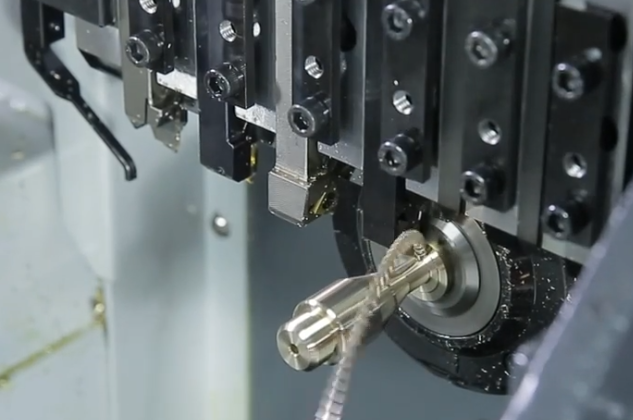

Types of CNC Lathes

Key categories include:

- 2-axis CNC lathe: Basic X and Z axes, ideal for standard shafts and bushings.

- Slant-bed CNC lathe: Bed has an inclined design for better chip flow and rigidity; widely used in production.

- Multitasking turning center: Includes C-axis, Y-axis, live tooling, and often sub-spindle; enables complete machining of complex parts.

- Swiss-type (sliding headstock) lathe: Uses a guide bushing to support long slender workpieces; common in medical, electronics, and precision components.

Axis Configuration and Features

Typical axis layout for turning centers:

- X-axis: Radial tool movement, controls diameter

- Z-axis: Axial tool movement along spindle centerline

- C-axis: Spindle indexing or continuous rotation for milling/drilling features

- Y-axis: Off-center milling operations (available on Y-axis lathes)

Feature options include servo-driven turrets, live tooling, bar feeders, parts catchers, and automatic chip conveyors.

Typical Specifications

Important parameters for CNC lathes:

- Maximum turning diameter and length (e.g., Ø300 mm × 500 mm)

- Spindle bore and chuck size (e.g., 52 mm bore with 8" chuck)

- Spindle speed: often 3,000–6,000 rpm for general lathes; higher on small precision machines

- Number of tools on turret: commonly 8–24 stations

- Positioning accuracy: typically ±0.005–0.01 mm for standard machines

- Bar capacity: important for automatic bar-fed production

Applications of CNC Turning

CNC turning is widely used in automotive (shafts, hubs, fasteners), hydraulics and pneumatics (valves, fittings, cylinders), medical (implant components, surgical instruments in Swiss lathes), and general machinery (rollers, pins, bushings). Turning centers with live tooling are often used to complete the entire part in one clamping by combining turning, drilling, and milling operations, reducing setup time and improving concentricity.

CNC Grinding Machines

CNC grinding machines are used to achieve tight tolerances and fine surface finishes on hardened or precision components. They remove small amounts of material using an abrasive grinding wheel instead of a cutting tool.

Grinding Principle and Control

Grinding uses a high-speed rotating abrasive wheel that cuts tiny chips from the workpiece surface. The CNC controller manages wheel speed, infeed, traverse, and positioning to achieve the required geometry and surface quality. The grinding wheel’s hardness, grain size, bond type, and dressing condition significantly affect performance.

Common Types of CNC Grinding Machines

Core CNC grinding machine types include:

- Cylindrical grinding machine: For external and internal cylindrical surfaces; workpiece rotates while the wheel traverses.

- Surface grinding machine: For flat surfaces; the wheel moves over a moving table or vice versa.

- Centerless grinding machine: Workpiece is supported between a regulating wheel and a grinding wheel, enabling high productivity for shafts and pins.

- Tool and cutter grinder: For grinding tools such as end mills, drills, and cutters with complex geometries.

Key Specifications and Parameters

Common specifications include:

- Maximum grinding length and diameter (e.g., Ø200 mm × 600 mm)

- Grinding wheel size: diameter, width, bore (e.g., Ø400 × 50 mm)

- Wheel speed: often 30–80 m/s peripheral speed

- Positioning accuracy: can reach sub-micron levels on high-end machines

- Surface roughness: typical Ra values from 0.2 µm to 0.05 µm or better

Applications of CNC Grinding

CNC grinding is used for hardened steel shafts, bearings, hydraulic cylinder rods, precision slides, gauges, dies, and cutting tools. It is especially critical in aerospace, automotive powertrain components, bearing manufacturing, precision tooling, and any application requiring high dimensional accuracy and low surface roughness.

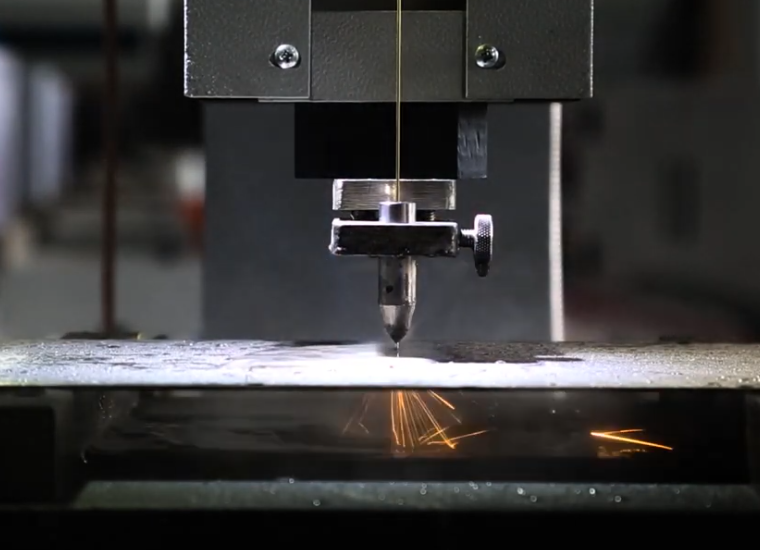

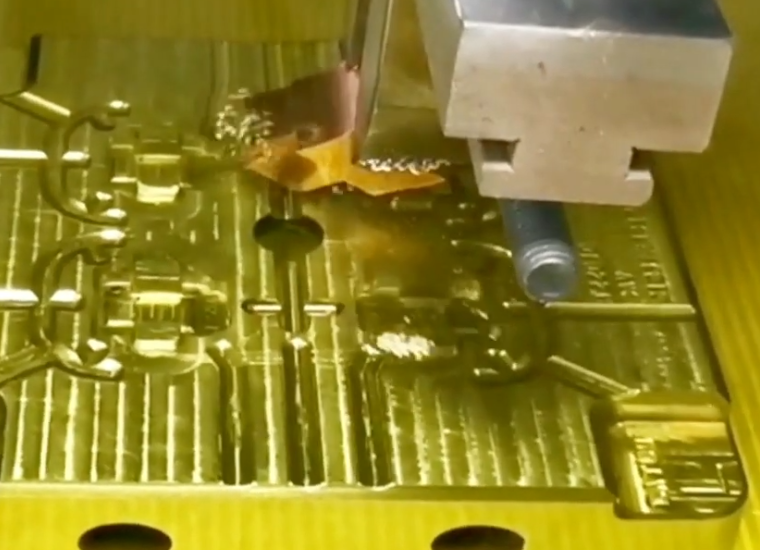

CNC EDM (Electrical Discharge Machining)

CNC EDM machines remove material using electrical discharges (sparks) between an electrode and the workpiece submerged in dielectric fluid. EDM can machine very hard materials and intricate shapes that are difficult or impossible to machine by conventional cutting.

EDM Working Principle

EDM uses controlled sparks generated by a DC or pulsed power supply. The sparks occur across a small gap between the tool electrode and the workpiece, both of which are electrically conductive. Each spark melts and vaporizes a tiny amount of material, which is then flushed away by the dielectric fluid.

The CNC controller regulates spark frequency, pulse duration, discharge energy, servo gap, and axis movement to shape the part according to the programmed path.

Types of CNC EDM Machines

Main EDM machine types include:

- Sinker EDM (die-sinking EDM): Uses a 3D shaped electrode (graphite or copper) that “sinks” into the workpiece to form negative shapes such as mold cavities.

- Wire EDM: Uses a continuously fed thin wire (usually brass or coated) as an electrode to cut profiles through the workpiece, similar to a contour cutting process.

- Hole drilling EDM (EDM drill): Uses tubular electrodes and high-speed sparking to drill small and deep holes, often starting holes for wire EDM.

Key Parameters and Capabilities

Important aspects of CNC EDM machines:

- Workpiece material: limited to electrically conductive materials (steel, carbide, titanium, Inconel, etc.)

- Surface finish: can achieve very fine finishes with low discharge energy

- Typical wire EDM wire diameters: approx. 0.1–0.3 mm

- Tapers and complex contours achievable due to multi-axis control

- Accuracy: wire EDM can typically achieve ±0.005 mm or better on many machines

Applications of CNC EDM

Sinker EDM is extensively used in mold and die manufacturing for forming cavities, ribs, and fine details. Wire EDM is widely applied to punch and die sets, extrusion dies, gear profiles, turbine components, and precision mechanical parts requiring sharp internal corners or complex profiles. EDM drilling is used for cooling holes in turbine blades, start holes for wire EDM, and deep small-diameter holes in hard materials.

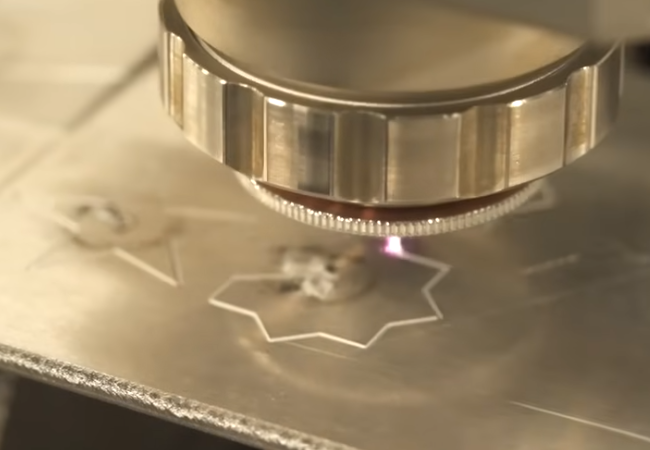

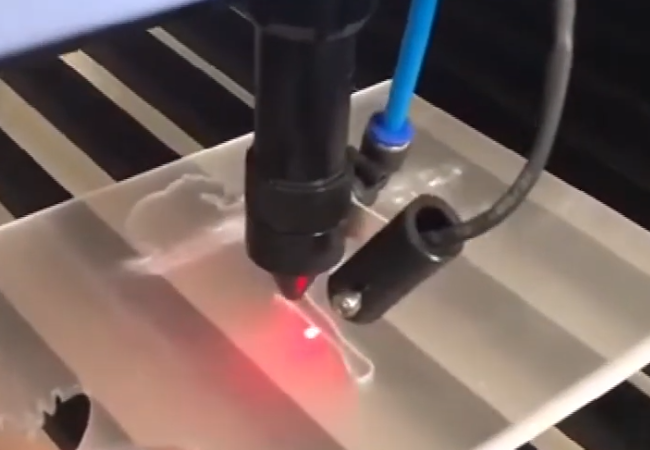

CNC Laser Cutting Machines

CNC laser cutting machines use a focused laser beam to cut, pierce, or engrave materials. They are prominent in sheet metal fabrication due to high cutting speeds, narrow kerf width, and clean edges.

Laser Cutting Principle

A laser source (CO₂, fiber, or Nd:YAG) generates a high-energy beam that is focused by lenses onto the workpiece surface. The intense energy melts, burns, or vaporizes the material, and an assist gas (oxygen, nitrogen, or air) expels the molten material from the kerf. The CNC system moves the laser head along programmed paths to produce the desired shapes.

Types of CNC Laser Machines

Typical laser cutting systems include:

- CO₂ laser cutting machine: Suitable for a wide range of materials including metals, plastics, wood, and textiles; often used in non-metal processing as well.

- Fiber laser cutting machine: Highly efficient for cutting metals, especially thin to medium thickness steels, stainless steel, aluminum, and non-ferrous metals.

- Hybrid or specialized systems: For tube cutting, 3D cutting on formed parts, or combined flat and tube cutting.

Key Specifications and Capabilities

Important parameters for CNC laser cutters:

- Laser power: typically from 1 kW up to 20 kW or more for industrial fiber lasers

- Maximum sheet size: such as 3000 × 1500 mm, 4000 × 2000 mm

- Maximum cutting thickness: depends on power and material, e.g., 10–25 mm for steel on mid- to high-power machines

- Positioning accuracy: often around ±0.03 mm or better

- Cutting speed: very high for thin sheets, enabling high productivity

Applications of CNC Laser Cutting

CNC laser cutting is widely used in sheet metal fabrication, electrical enclosures, chassis, automotive body components, signage, décor panels, and precision blanks. It is frequently chosen when flexible nesting of parts, rapid cutting of varied shapes, and reduced post-processing are required.

Comparing the 5 Main Types of CNC Machines

Each type of CNC machine has distinct operating principles and is suited to different part geometries, materials, and tolerances. Selecting the appropriate machine type is essential for achieving the required dimensional accuracy, surface quality, and production efficiency.

| CNC Machine Type | Typical Materials | Common Part Shapes | Typical Accuracy Range | Key Strength |

|---|---|---|---|---|

| CNC Milling | Metals, plastics, composites | Prismatic, 3D surfaces | ±0.005–0.02 mm | Versatile 3D machining |

| CNC Turning | Metals, plastics | Cylindrical, rotational | ±0.005–0.02 mm | Fast production of round parts |

| CNC Grinding | Hardened steels, carbides | Cylindrical, flat, tools | To sub-micron on high-end machines | Very high precision and finish |

| CNC EDM | Electrically conductive materials | Intricate cavities, sharp corners | ±0.005 mm or better | Machines hard materials and complex shapes |

| CNC Laser Cutting | Metals, some non-metals | Flat sheet profiles, thin-wall tubes | ±0.03 mm or better | High-speed sheet cutting |

Key Components Shared by Most CNC Machines

Despite differences in cutting principles, most CNC machine types share several core components that determine performance and reliability.

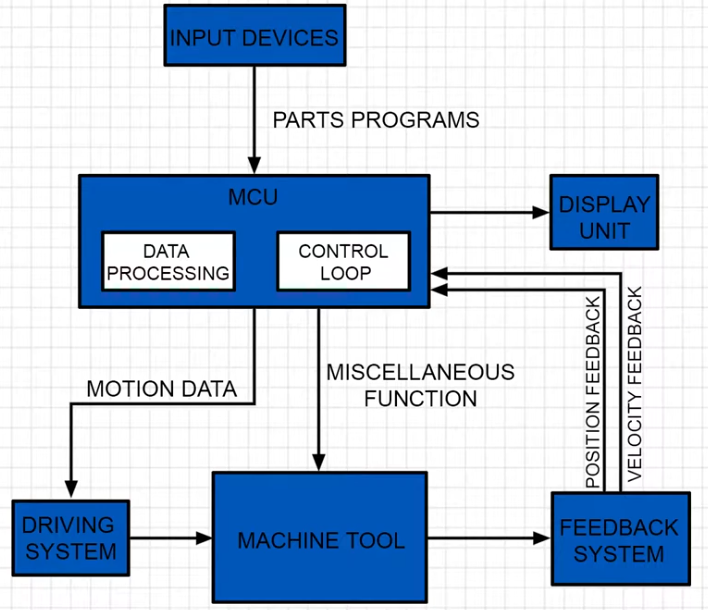

CNC Controller and Drive System

The CNC controller interprets the part program (G-code) and generates motion commands. Servo drives and motors convert these commands into precise movement along linear and rotary axes. Features such as look-ahead, interpolation algorithms, and high-speed processing influence machining accuracy and cycle time.

Machine Structure and Guideways

The machine base, column, and table or carriage form the structural backbone. High rigidity and thermal stability are important for minimizing deformation and maintaining accuracy. Linear guideways or box ways support axis motion, with ball screws or linear motors providing drive. For precision grinding and high-end milling, thermal compensation and temperature control are often employed.

Spindle or Tool System

The spindle or tooling system holds and rotates the cutting tool, grinding wheel, wire, or laser optics. Parameters such as spindle power, speed, torque, taper interface, and bearings are key performance indicators. Automatic tool changers enable long unattended machining cycles in milling and turning centers.

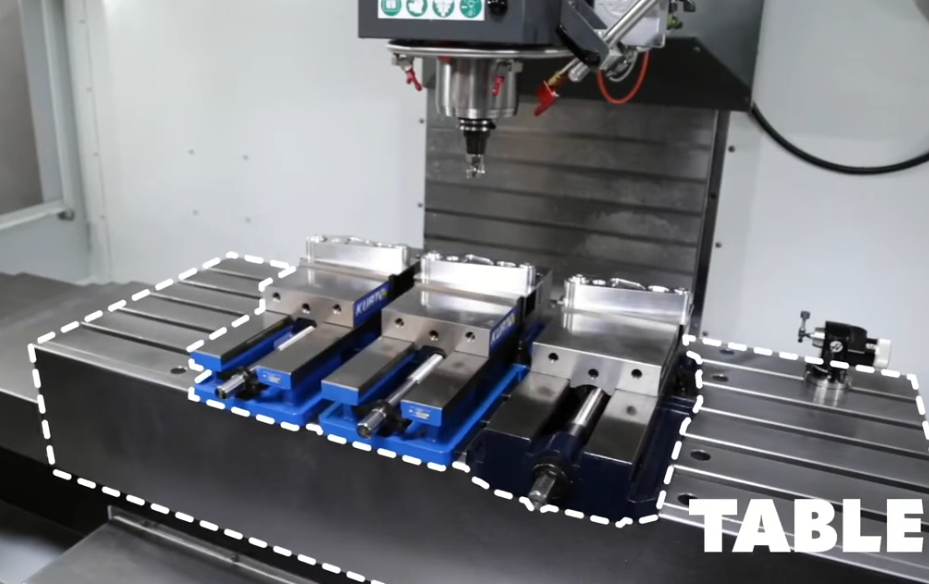

Workholding and Fixture Systems

Chucks, collets, vises, pallets, magnetic tables, and custom fixtures secure the workpiece. Adequate clamping force, accessibility for tools, and repeatable positioning are essential. On production lines, standardized pallets and modular fixturing systems reduce setup time and improve process stability.

Key Considerations When Choosing a CNC Machine

Selecting the appropriate CNC machine type and configuration depends on the part specifications, material properties, production volumes, and tolerance requirements.

Part Geometry and Tolerance Requirements

Rotational parts with tight concentricity requirements are typically produced on CNC lathes or multitasking turning centers. Prismatic and complex 3D parts with pockets and contours are suited to CNC milling and 5-axis machining. Hardened surfaces and extremely tight tolerances might require CNC grinding as a finishing operation. Intricate internal cavities, narrow slots, and sharp internal corners in hard materials are often produced by EDM. Sheet metal profiles and nestings are efficiently cut by CNC laser machines.

Material Type and Mechanical Properties

Metals, plastics, and composites can be machined on milling and turning machines, although cutting parameters vary with hardness and toughness. Hardened steels and carbides are usually finished by grinding or EDM. Reflective or highly conductive metals require appropriate laser types and parameter selections for efficient cutting.

Production Volume and Automation Level

High-volume production favors machines with automation options such as bar feeders, pallet changers, robotic loading, or automatic part handling. CNC lathes and machining centers with standardized fixtures are typical in mass production. For smaller batches or high-mix/low-volume manufacturing, flexibility and quick changeover become critical, making 3- to 5-axis machining centers and integrated CAM programming essential.

Pain Points and Practical Constraints

Typical practical issues in selecting and using CNC machines include ensuring adequate rigidity and thermal stability for the required tolerances, controlling chip removal and coolant management on milling and turning machines, managing wheel wear and dressing cycles on grinding machines, controlling electrode wear and flushing efficiency on EDM, and choosing appropriate laser power and assist gas configuration to balance cutting quality and operating cost. Careful analysis of part requirements and process planning can significantly reduce these complications.

Conclusion

The 5 main types of CNC machines—CNC milling machines, CNC lathes and turning centers, CNC grinding machines, CNC EDM machines, and CNC laser cutting machines—cover the majority of machining needs in modern manufacturing. Each type has distinct strengths related to part geometry, material compatibility, accuracy, and surface quality. By understanding the operating principles, configurations, and capabilities of each machine type, engineers and manufacturing professionals can design efficient process routes, select suitable equipment, and achieve consistent, high-quality production.

FAQ About CNC Machine Types

What are the main types of CNC machines?

The main types include CNC milling machines, CNC lathes (turning centers), CNC routers, CNC plasma cutters, CNC laser cutters, CNC EDM machines, and CNC grinding machines.

What is the difference between a CNC lathe and a CNC mill?

A CNC lathe rotates the workpiece while a stationary cutting tool shapes it, making it ideal for round parts like shafts. A CNC mill keeps the workpiece stationary while rotating cutting tools shape the material.

What is the difference between 3-axis, 4-axis, and 5-axis CNC machines?

A 3-axis machine moves in X, Y, and Z directions. A 4-axis machine adds rotation around one axis. A 5-axis machine adds rotation around two axes, allowing complex machining from multiple angles without repositioning.

Which CNC machine is best for beginners?

CNC routers and small CNC milling machines are generally best for beginners due to their lower cost, easier operation, and wide range of applications.

How do I choose the right CNC machine type?

The right machine depends on your material, part complexity, production volume, and budget. For metal parts, choose mills, lathes, or EDM. For wood and plastics, routers and laser machines are often better.