Sensor housings play a decisive role in the reliability, accuracy and lifetime of sensing devices. The housing is not only a protective mechanical shell; it is a functional part of the measurement chain that affects thermal behavior, response time, chemical resistance, electromagnetic immunity and installation quality. This guide provides a systematic, in‑depth overview of sensor housings, covering enclosure types, materials, ratings, mechanical design details and application-specific considerations for industrial, automotive, building, medical and outdoor environments.

Fundamentals of Sensor Housings

Before selecting or designing a sensor housing, it is important to understand its core functions and key performance parameters. A housing must create a suitable environment for the sensor element while ensuring correct interaction with the measured variable.

Core functions of a sensor housing

- Mechanical protection: Shields delicate sensing elements and electronics from impact, vibration, abrasion and mechanical stress.

- Environmental sealing: Prevents ingress of dust, water, oils, process media and other contaminants that could cause failure or drift.

- Chemical and corrosion resistance: Protects against corrosive gases, acids, alkalis, solvents, cleaning agents and salt spray.

- Thermal management: Controls heat transfer to the sensing element and electronics, supporting accurate measurements and component reliability.

- Electromagnetic shielding: Reduces susceptibility to electromagnetic interference (EMI) and radio-frequency interference (RFI), especially in industrial and automotive environments.

- Mechanical interface: Provides standardized threads, flanges, mounting holes and alignment features for repeatable installation and easy replacement.

- Cable and connector interface: Integrates glands, strain relief and connectors for reliable electrical connection.

- Safety and compliance: Enables certification for IP, NEMA, ATEX, IECEx, UL and other standards through controlled design and robust construction.

Key performance parameters

When engineers evaluate sensor housings, several parameters are typically considered:

- Protection degree (IP or NEMA rating)

- Impact resistance and mechanical load capability

- Operating temperature range and thermal stability

- Chemical resistance profile and corrosion class

- Pressure rating or vacuum capability (if relevant)

- Material properties (conductivity, dielectric strength, thermal conductivity, weight)

- Dimensions, tolerances and form factor constraints

- Mounting and connection options

- Compliance with industry-specific regulations

Common Types of Sensor Housings

Sensor housings vary widely according to the type of physical quantity measured, installation environment and mechanical interface. The following categories cover the most frequently used housing types across industries.

Cylindrical proximity and presence sensor housings

Cylindrical housings are widely used for inductive, capacitive, magnetic and photoelectric proximity sensors. They typically feature:

- Standard thread sizes: M8, M12, M18, M30, M36 or 1/2", 3/4" NPT

- Body materials: nickel-plated brass, stainless steel, plastic (PBT, PA, POM) or hybrid metal/plastic designs

- Flush and non-flush mounting variants affecting sensing distance and field geometry

- Integral cable or M8/M12 connector termination

- Flat or domed sensing face made of plastic or glass

These housings are commonly used in automation lines, material handling and packaging machines. Their standardized dimensions permit easy replacement between manufacturers.

Rectangular and block-style housings

Rectangular sensor housings are preferred when low profile, flat mounting or directional alignment of the sensing field is required. Features typically include:

- Compact or elongated block shapes for narrow machine spaces

- Multiple mounting holes and slots for flexible alignment

- Flush sensing faces with integrated optics or coils

- Side or rear cable exit to suit wiring paths

These housings are used for photoelectric sensors, distance sensors, inductive sensors and small ultrasonic sensors in conveyor systems and assembly lines.

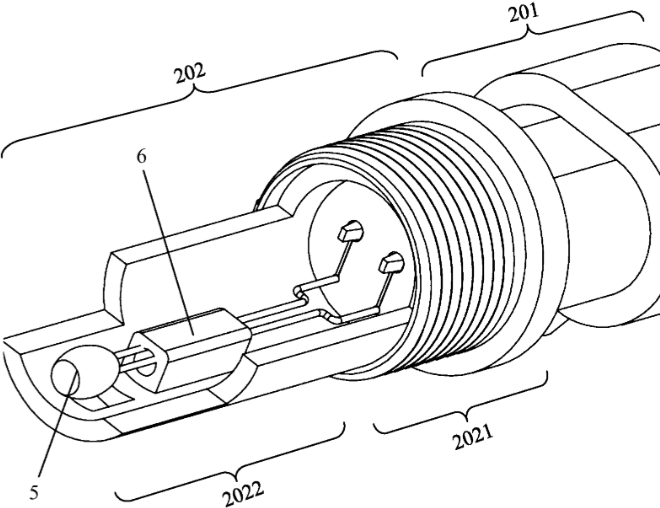

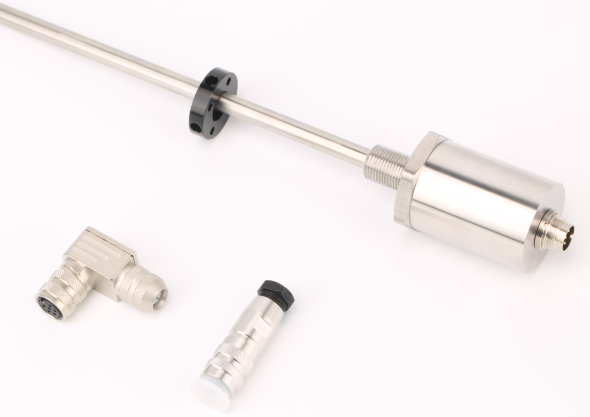

Threaded probe and immersion housings

Probe-style housings are common for temperature, humidity, gas and liquid sensors. Typical features are:

- Rod or tube form factor with defined insertion length

- Process threads such as G1/4, G1/2, NPT, SAN, tri-clamp or custom flange connections

- Immersion sleeves or thermowells for temperature sensors

- Perforated or sintered protective caps for humidity and gas sensors

- Pressure-resistant designs for pipework and vessels

They are applied in HVAC, process engineering, water treatment and heating systems. The housing must provide secure sealing to the process medium and, for some sensors, minimal flow resistance.

Flanged and sanitary sensor housings

Sanitary and process industries like food, beverage and pharmaceuticals require housings that meet hygienic design rules. These housings typically include:

- Flanges or hygienic process connections such as tri-clamp, Varivent or aseptic couplings

- Polished stainless steel surfaces with defined surface roughness (for example Ra ≤ 0.8 µm)

- Smooth transitions and absence of dead zones to avoid contamination

- Seals compliant with food and pharmaceutical regulations

Flanged housings are also used for flow, pressure, level and analytical sensors where a robust process connection is required.

Miniature housings for embedded and PCB sensors

Miniature housings are used when sensors are integrated into handheld devices, wearables, consumer electronics or compact control units. Characteristics include:

- Very small outer dimensions with tight tolerances

- Compatibility with reflow or wave solder processes for PCB-mounted sensors

- Use of technical plastics or metal inserts for mechanical stability

- Special apertures for optical, gas or pressure access to the sensing element

These housings often integrate clips, snap-fits and alignment features to position the sensor relative to displays, user interfaces or external ports.

Rugged industrial and field enclosures

Industrial and outdoor sensor systems frequently require separate enclosures for electronics and wiring. Typical enclosures include:

- Die-cast aluminum, stainless steel or reinforced plastic boxes

- Terminal compartments with cable glands and internal DIN rail

- Windows or domes for optical sensors and radar devices

- EMC gaskets and internal shielding

These housings host remote sensor heads, gateways, signal conditioners or multi-sensor assemblies and can achieve high IP or NEMA ratings for harsh environments.

Materials for Sensor Housings

Material selection is critical because it determines the housing’s mechanical strength, chemical resistance, weight, thermal behavior and cost. The most common material families are metals, plastics, elastomers and glass/ceramic components.

Metallic housing materials

Metals are chosen for their mechanical robustness, thermal conductivity and shielding capabilities.

Stainless steel

Stainless steel is widely used in hygienic, corrosive and high-temperature environments. Key characteristics include:

- High corrosion resistance in water, steam, many chemicals and cleaning agents

- Good mechanical strength and wear resistance

- Working temperature typically from −40 °C up to 200–400 °C depending on grade and seal selection

- Easy to clean and polish for sanitary applications

Common stainless steel grades for sensor housings include 1.4301 (AISI 304) for general use and 1.4404/1.4571 (AISI 316L/316Ti) for aggressive media and marine environments.

Brass and nickel-plated brass

Brass housings are frequently used for inductive and capacitive sensors. Nickel-plated surfaces improve wear and corrosion resistance. Characteristics:

- Good machinability for threaded bodies and fine features

- Moderate corrosion resistance; enhanced with nickel plating

- High dimensional stability and mechanical strength

- Typical operating temperature range from −25 °C to +70 or +85 °C, depending on internal components

These housings are suitable for many industrial automation environments, but for aggressive chemicals or seawater, stainless steel is usually preferred.

Aluminum and die-cast alloys

Aluminum enclosures offer a favorable strength-to-weight ratio and good heat dissipation. They are common in field junction boxes and electronic sensor modules. Features include:

- Light weight compared to steel and brass

- Good thermal conductivity for heat management

- Corrosion resistance improved by powder coating or anodizing

- Suitability for complex shapes via die casting

Typical temperature ranges depend on gasket and electronics design but often span from −40 °C to +80 or +105 °C.

Plastics for sensor housings

Engineering plastics provide design flexibility, low weight and electrical insulation. They are used in many proximity, optical and environmental sensors.

PBT (polybutylene terephthalate)

PBT is widely used because of its good dimensional stability, resistance to moisture and many chemicals, and suitability for injection molding. Attributes include:

- Good mechanical strength and stiffness

- Moderate to good chemical resistance (oils, greases, many solvents)

- Low water absorption compared to some other engineering plastics

- Typical continuous use temperature up to about +100 to +120 °C for standard grades

Glass-fiber reinforced PBT grades are used where higher rigidity and dimensional stability are required.

PA (polyamide, nylon)

Polyamide is used for sensor housings that require impact resistance and durability. Features:

- High mechanical toughness and impact resistance

- Good wear properties

- Higher moisture absorption than PBT, which may influence dimensions

- Typical use temperature up to about +80 to +120 °C, depending on type

PA6 and PA66 are common for cable glands, connectors and some sensor housings, often with glass fiber reinforcement.

Other plastic materials

Additional plastics appear in specialized housings:

- PC (polycarbonate) for transparent covers and high impact resistance

- ABS for cost-effective enclosures in non-demanding environments

- POM (acetal) for low-friction applications

- PEEK for high-temperature and high-chemical-resistance environments

The choice of plastic must consider UV stability, flammability rating, chemical exposure and long-term dimensional stability.

Elastomers for seals and gaskets

Elastomeric materials form the interface between housing parts and provide sealing performance. Common materials include:

- NBR (nitrile rubber) for oils and fuels, typical temperature −20 to +100 °C

- EPDM for water, steam and many chemicals, typical temperature −40 to +120 °C

- FKM (Viton) for high temperature and aggressive chemicals, typical temperature −20 to +200 °C

- Silicone rubber for wide temperature ranges, often −50 to +200 °C

Seal geometry, compression and surface finish of mating parts are critical factors for achieving the intended IP or NEMA rating.

Glass, ceramics and sapphire

Optical and high-temperature sensors often require windows or protective layers made of glass or ceramic materials. Examples include:

- Borosilicate glass windows for optical and infrared sensors

- Sapphire windows for abrasive or high-pressure environments

- Ceramic housings for high-temperature and high-voltage isolation

These materials provide transparency or electrical insulation while resisting thermal shock and mechanical loads.

Protection Ratings: IP and NEMA for Sensor Housings

One of the most important specification aspects for sensor housings is the degree of ingress protection against dust and water. Two widely used standards are the IP (Ingress Protection) rating and the NEMA enclosure types.

IP (Ingress Protection) ratings

IP ratings follow IEC 60529 and indicate the level of protection against solid objects and liquids. The format is IP followed by two digits. The first digit describes protection against solids and contact; the second digit describes protection against water ingress.

| IP rating | Solid protection | Water protection | Typical application environment |

|---|---|---|---|

| IP20 | Protected against fingers and medium-sized objects | No protection against water | Control cabinets, dry indoor environments |

| IP40 | Protected against most wires and small tools | No water protection | Indoor electronics, general-purpose housing |

| IP54 | Limited protection against dust (no harmful deposits) | Protection against water splashes from any direction | Workshops, indoor machinery with occasional splashing |

| IP65 | Dust-tight | Protected against water jets | Industrial machines, washdown areas with limited exposure |

| IP67 | Dust-tight | Protected against temporary immersion (up to 1 m, time-limited) | Outdoor installations, wet environments, temporary submersion |

| IP68 | Dust-tight | Protected against continuous immersion under conditions specified by manufacturer | Permanent underwater use or high humidity environments |

| IP69 | Dust-tight | High-pressure, high-temperature water jets | Food and beverage washdown, heavy cleaning processes |

When specifying an IP rating for a sensor housing, engineers should consider not only the nominal rating but also real-world factors such as cable entry quality, installation practices, aging of seals and potential for mechanical damage.

NEMA enclosure types

In North America, NEMA (National Electrical Manufacturers Association) enclosure type designations are widely used. NEMA types define protection against environmental conditions including dust, water, ice, corrosion and occasionally oil. Common NEMA types relevant for sensors include:

- NEMA 1: General-purpose indoor use, protection against limited dust and contact.

- NEMA 3/3R: Outdoor use, protection against rain, snow, and sleet; some resistance to windblown dust.

- NEMA 4/4X: Indoor or outdoor use, protection against splashing and hose-directed water; 4X adds corrosion resistance.

- NEMA 6/6P: Protection against occasional or prolonged submersion; 6P adds corrosion protection and extended immersion capability.

Although there is no direct one-to-one mapping between IP and NEMA ratings, an approximate correlation can help in international projects. For example, NEMA 4X generally corresponds to at least IP66/IP67 capabilities in terms of dust and water ingress.

Mechanical Design Aspects of Sensor Housings

The mechanical construction of a sensor housing determines its robustness, sealing performance and ease of assembly. Attention to detail during design reduces installation errors and field failures.

Wall thickness and reinforcement

Wall thickness must balance mechanical strength, thermal conduction, weight and manufacturing constraints. Important considerations include:

- Minimum thickness to withstand external impact and internal pressure loads

- Reinforcing ribs or gussets in plastic housings to reduce deformation

- Uniform wall thickness where possible to minimize internal stresses during molding

- Allowance for machining of threads or sealing surfaces without compromising strength

For metal housings, localized reinforcement may be used around threads, connector interfaces and mounting points.

Sealing interfaces and gasket design

Achieving a specified IP rating depends strongly on the design of sealing interfaces. Key elements include:

- Groove and land dimensions matched to gasket cross-section and hardness

- Controlled compression (often 20–30% for many elastomer gaskets) to ensure lasting sealing without over-stressing the material

- Surface roughness and flatness appropriate for O-rings or flat gaskets

- Protection of seals from direct UV exposure and mechanical damage

- Use of formed-in-place gaskets (FIPG) where automation and repeatability are essential

Screws or clamps that compress the gasket should be positioned to provide uniform pressure along the seal perimeter.

Threads, flanges and mounting features

Sensor housings require reliable mechanical interfaces to machines, pipes or structures. Common features:

- Metric or imperial external threads (for example M12×1, M18×1, 1/2" NPT) for direct mounting

- Internal threads for adapter fittings or protective caps

- Flanges with standardized bolt circle diameters for process connections

- Keying surfaces and flats for wrench tightening and orientation

Mechanical tolerances must ensure correct alignment of the sensing element relative to the measured medium or target, especially for optical, ultrasonic and radar sensors.

Cable glands and connectors

The transition from sensor housing to cabling is a frequent weak point in environmental sealing. Options include:

- Integrated molded cables with strain relief, often providing high IP rating

- Cable glands with compression seals for various cable diameters

- M8/M12 circular connectors or other industrial connectors with O-rings or gaskets

Correct tightening torque, selection of suitable gasket materials and compatibility with cable sheath materials are essential to maintain long-term ingress protection.

Internal layout and component mounting

Inside the housing, the arrangement of PCBs, sensor elements and wiring influences performance and reliability. Considerations include:

- Mechanical decoupling of sensitive elements from housing vibrations via elastomer mounts or flexible supports

- Minimizing thermal gradients that could affect measurement accuracy

- Providing venting or pressure equalization elements where needed to avoid stress on seals

- Routing wires to avoid chafing and to maintain clearance to high-voltage parts

Mechanical stops, tabs and bosses are often integrated into the housing to position internal components precisely and to secure them against shock loads.

Thermal Behavior and Sensor Housing Design

Thermal characteristics of sensor housings affect measurement accuracy, response time and component lifetime. The housing serves as a heat path between the environment, the sensor element and any internal heat sources.

Thermal conductivity and material selection

Metals such as aluminum and copper alloys have high thermal conductivity and can quickly transfer heat from the medium to the sensor. Plastics have much lower thermal conductivity and provide thermal isolation. Engineers must match material properties to the sensing requirement:

- Temperature sensors may benefit from metallic housings that minimize thermal lag.

- Electronics that require low operating temperature may use metal housings as heat sinks.

- Sensors that must be thermally isolated from external fluctuations may use plastic or composite housings.

Heat conduction paths should be modeled where necessary, especially in high-accuracy applications.

Response time of temperature sensors and thermowells

In process automation, temperature sensors are often inserted into thermowells or protective tubes. While thermowells provide mechanical protection and allow sensor replacement during operation, they also introduce extra thermal mass and conduction paths. This increases response time compared to direct immersion. Important parameters are:

- Wall thickness and material of thermowell

- Gap between sensor element and inner wall of thermowell

- Insertion length into the process medium

- Flow speed of the medium around the thermowell

Design must balance protection and measurement dynamics, taking into account process safety requirements and sensor specifications.

Heat dissipation for electronics

Sensors often contain active electronics such as signal conditioning circuits, microcontrollers and wireless modules. Housing design affects cooling of these components. Effective strategies include:

- Thermal coupling of heat sources to metallic housing parts using thermal pads or compounds

- Adequate internal air volume or external fins to increase heat dissipation surface

- Use of light-colored outer surfaces in outdoor applications to reduce solar heat absorption

- Limiting thermal resistance between internal components and ambient environment

Thermal design must respect maximum temperature ratings for semiconductors, battery cells and other sensitive parts.

Environmental and Chemical Resistance

Sensor housings are exposed to diverse environmental conditions including moisture, chemicals, UV radiation and mechanical wear. Proper material selection and surface treatment are crucial to maintain functionality over the entire service life.

Chemical compatibility

Depending on the application, housings can be in contact with oils, coolants, fuels, acids, alkalis, disinfectants and solvents. Important aspects include:

- Compatibility between housing material and process media based on chemical resistance charts and test data

- Resistance of seals and gaskets to swelling, embrittlement or softening

- Impact of repeated cleaning and sterilization procedures

Examples: stainless steel 316L with FKM or EPDM seals for many chemical processes; PBT or PA with suitable seals for machine tools and lubrication environments.

UV and weather resistance

Outdoor sensor housings must withstand UV radiation, temperature cycling, rain, snow and often salt spray. Design factors include:

- UV-stabilized plastics or metal housings with suitable coatings

- Corrosion-resistant fasteners and mounting accessories

- Drainage paths or weep holes where appropriate to prevent condensation accumulation

Salt-fog testing and accelerated weathering tests are often used to validate long-term durability of outdoor sensor housings.

Mechanical wear and abrasion

Sensors exposed to moving media or abrasive particles, such as flow sensors in slurries or optical sensors in dusty environments, must resist wear. Measures include:

- Use of hardened stainless steel or ceramic tips for abrasive contact

- Replaceable protective caps or windows

- Flow-optimized designs to reduce local velocities and impact angles

Periodic inspection and replacement intervals should be defined for components that face intense wear.

Overview of Application-Specific Housing Requirements

Each application area imposes distinct requirements on sensor housings. The following overview summarizes typical constraints and suitable housing characteristics.

| Application domain | Key environmental conditions | Typical housing materials | Typical protection rating |

|---|---|---|---|

| Factory automation | Oil mist, coolant, occasional water jets, vibration | Nickel-plated brass, stainless steel, PBT/PA plastics | IP65–IP67, sometimes IP69 in washdown zones |

| Process industry | Pressurized lines, chemicals, high temperatures | Stainless steel, high-performance alloys, PEEK | IP66–IP67, high pressure and temperature ratings |

| Food and beverage | Frequent cleaning, hot water, cleaning agents | Polished stainless steel 316L, FDA-compliant seals | IP69, hygienic design requirements |

| Building automation | Indoor air, moderate humidity, aesthetics important | ABS/PC plastics, decorative covers, sometimes metal | IP20–IP54 depending on location |

| Automotive and transportation | Vibration, oils, temperature cycling, splash water | Reinforced plastics, aluminum, stainless steel | IP54–IP69 depending on mounting position |

| Outdoor infrastructure | UV, rain, snow, wind, salt spray | UV-stable plastics, coated aluminum, stainless steel | IP65–IP67 or higher for exposed installations |

| Medical devices | Cleaning and disinfection, controlled environments | Biocompatible plastics, stainless steel, glass | IP20–IP67 depending on device type and use |

Industrial and Automation Sensor Housings

Industrial automation places high demands on sensor housings due to continuous operation, dynamic loads and exposure to oils and coolants. Typical use cases include position sensing, object detection, speed measurement and distance control.

Inductive and capacitive proximity sensors

These sensors often use cylindrical metal housings with the following characteristics:

- Nickel-plated brass or stainless steel bodies with M8, M12, M18 or M30 threads

- Flush and non-flush installation options that influence sensing range

- Glass-filled PBT sensing faces with sealed interfaces to the metal body

- Integrated LED indicators for power and switching state

Mechanical design must prevent deformation of the sensing face during tightening and ensure that the sensing coil remains stable in relation to the housing.

Photoelectric and laser sensors

Photoelectric sensors use optical components housed behind protective windows. Housing requirements include:

- Precise alignment of emitter and receiver optics

- Scratch-resistant and dirt-repellent windows, sometimes with anti-reflection coatings

- Protection against internal condensation that could obscure optics

Rectangular plastic housings with integrated mounting slots are common. For laser sensors, metallic housings may be used to dissipate heat from laser diodes and to increase mechanical rigidity.

Ultrasonic and radar sensors

Ultrasonic sensors rely on a vibrating transducer, often integrated in a protective front surface. Radar sensors use antennas located behind radomes or lenses. Housing considerations:

- Acoustically or electromagnetically transparent front material with stable properties over temperature

- Mechanical decoupling to avoid parasitic vibrations for ultrasonic sensors

- Integrated water runoff and contamination-minimized geometry to keep front surface clean

For radar sensors used in outdoor level measurement, robust metal back housings with plastic or PTFE radomes are typical.

Environmental sensors in industrial settings

Pressure, temperature and humidity sensors installed on processes or in air ducts require protective housings with robust process connections. Design features include:

- Metallic process connection with defined pressure rating

- Protective sintered caps or filters to prevent contamination while allowing pressure or humidity access

- Cable or connector interfaces with strain relief

Temperature sensors with thermowells are common in high-pressure and high-temperature media, enabling replacement without breaking process containment.

Automotive Sensor Housings

Automotive sensors operate in challenging conditions involving vibration, temperature extremes, fluids and contaminants. Housing design must comply with automotive standards and production requirements.

Engine and powertrain sensors

Sensors for engine management, exhaust systems and transmissions include temperature, pressure, position and speed sensors. Typical housing features:

- High-temperature-resistant plastics (for example PA, PBT, PPS) or metal housings for hot zones

- Sealed connectors that meet automotive ingress protection and vibration requirements

- Chemical resistance to fuels, oils, coolants and exhaust condensates

Integrated brackets or flanges provide defined mounting positions relative to rotating parts such as crankshafts or camshafts.

Chassis and safety sensors

Sensors for ABS, ESP, airbag systems and ride control require robust housings with precise mounting. Characteristics include:

- Compact housings integrated into brake assemblies or suspension components

- Protection against road splash, salt and stone impact

- Overmolded cable connections for long-term sealing and strain relief

Mechanical interfaces must ensure consistent air gaps and positioning for magnetic speed sensors and accelerometers.

Interior and body sensors

Interior sensors measure temperature, humidity, light and occupancy. Housing design focuses on integration and aesthetics:

- Discreet housings integrated into headliners, dashboards or door panels

- Perforations or slits for air exchange or light entry with controlled directional characteristics

- Materials and colors matched to vehicle interior design

Interior housings often combine multiple sensors in one assembly, requiring careful layout of openings and shielding between different sensing functions.

Building Automation and HVAC Sensor Housings

In building automation, sensors monitor temperature, humidity, CO2, presence, light levels and air quality. Housings must be unobtrusive, easy to install and suitable for the building’s environmental and aesthetic requirements.

Room sensor housings

Room sensors for temperature and humidity are usually mounted on walls or ceilings. Key considerations:

- Ventilation openings that allow sufficient air flow around the sensor element

- Design that minimizes the influence of wall temperature and drafts

- Non-yellowing plastics and discrete design

Some housings support optional displays or user interfaces, such as setpoint knobs or buttons, requiring clearly separated internal zones for user input and sensor measurement.

Duct and outdoor sensor housings

Duct sensors measure temperature, humidity or flow in ventilation channels. Housings often consist of:

- A head section containing electronics and terminal connections

- A probe or rod that projects into the air stream

- Mounting plates or nipples for duct insertion

Outdoor sensors for building automation require weather shields to avoid direct solar radiation and rain from influencing measurements. These shields include louvered or aspirated designs that promote air exchange while blocking direct radiation.

Medical, Laboratory and Cleanroom Sensor Housings

Medical and laboratory applications impose strict requirements on cleanliness, disinfectability and sometimes biocompatibility. Sensor housings for such environments must withstand repeated cleaning cycles and help avoid contamination.

Contact and non-contact medical sensors

Examples include temperature probes, pressure sensors and optical sensors. Housing considerations:

- Use of materials compliant with biocompatibility standards where contact with patients occurs

- Smooth surfaces without crevices, enabling effective cleaning and sterilization

- Sealing that maintains IP rating during disinfection

For non-contact sensors such as pulse oximetry, housings incorporate optical windows with defined spectral transmission and resistance to disinfectants.

Cleanroom and laboratory sensors

In cleanrooms and laboratories, particle release and chemical compatibility are critical. Housing design focuses on:

- Low particle-emitting materials and coatings

- Minimal edges and joints to reduce deposition and simplify cleaning

- Resistance to cleaning agents and sterilization methods used in the facility

Mounting systems often allow sensor removal for calibration with minimal disruption to cleanroom integrity.

Outdoor, Marine and Agricultural Sensor Housings

Sensors used in outdoor, marine and agricultural environments face moisture, temperature cycling, dirt and mechanical impacts. Housings must provide long-term durability under these conditions.

Infrastructure and environmental monitoring sensors

Sensors monitoring air quality, weather, water levels or structural health rely on housings with:

- UV-stabilized and corrosion-resistant materials

- Ingress protection against rain, snow and occasional submersion

- Vent elements that permit gas exchange while blocking water and particulates where required

Mounting hardware must withstand wind loads and prevent galvanic corrosion between different metals.

Marine and offshore sensor housings

Marine sensors are exposed to saltwater, biofouling and wave impacts. Housing characteristics include:

- Use of stainless steel or corrosion-resistant alloys and plastics compatible with seawater

- Sealed interfaces tested for pressure and long-term immersion

- Optional anti-fouling coatings or mechanical cleaning features

Design may include pressure compensation elements to handle atmospheric or depth-related pressure changes while protecting seals.

Agricultural and smart farming sensors

Sensors in agriculture measure soil moisture, weather, fertilizer levels and machine parameters. Housing requirements:

- Resistance to fertilizers, pesticides and field dirt

- Robust design to withstand impacts from equipment and animals

- Long-term outdoor stability for battery-powered wireless nodes

For soil sensors, housings often have specific geometries to ensure consistent soil contact and to avoid water accumulation around sensitive parts.

Electrical and EMC Considerations in Housing Design

The housing influences electromagnetic compatibility and electrical safety. Appropriate design and material selection reduce interference and protect against electrical hazards.

EMI/RFI shielding

Metal housings or metallized plastic housings can act as shields against electromagnetic fields. Important aspects include:

- Continuous conductive paths across housing seams via conductive gaskets or surface treatments

- Proper grounding of the housing to a defined reference point

- Filtered or shielded connectors to limit conducted interference

For sensors with integrated RF modules, the housing must allow intended radio emissions while shielding sensitive analog circuitry from external interference.

Grounding and insulation

Depending on the application, the housing may serve as a protective earth or must be isolated from live parts. Design considerations:

- Defined protective earth connection points for metal housings

- Clear creepage and clearance distances between conductive parts and housing as per relevant standards

- Use of insulating plastic housings where galvanic isolation is required

Labeling and documentation must indicate grounding requirements to installers and maintenance personnel.

Installation, Maintenance and Service Aspects

Well-designed sensor housings facilitate straightforward installation and maintenance, reducing downtime and service costs.

Mounting ergonomics and access

The housing should allow installation with standard tools and provide clear access to mounting points and connectors. Features include:

- Wrench flats on cylindrical sensors and accessible screw heads on rectangular housings

- Mounting brackets or adapters for flexible installation positions

- Clear orientation markers for correct alignment of sensing direction

Installation instructions should specify tightening torques and recommended mounting surfaces to avoid housing deformation.

Serviceability and replacement

During maintenance, sensors may need to be replaced or repositioned. Housing features that support serviceability include:

- Pluggable connectors instead of permanently attached cables where feasible

- Standardized mounting patterns and threads

- Replaceable protective caps, windows or filters

In process applications, thermowells allow removal of temperature sensors without interrupting the process medium, provided the thermowell remains intact and sealed.

Labeling and identification

Clear labeling on the housing aids maintenance and troubleshooting. Typical elements:

- Type designation and part number

- Electrical ratings and connection diagrams

- Protection ratings and certification marks

Laser marking, engraving or durable labels should be used to ensure readability over the lifetime of the sensor, even in aggressive environments.

Selection Guidelines for Sensor Housings

Selecting a suitable sensor housing involves combining information about the sensor element, operating environment and mechanical interface. The following guidelines support systematic selection.

Define environmental and mechanical requirements

First, specify the conditions the housing must withstand:

- Expected range of ambient and process temperatures

- Exposure to water, dust, oils, chemicals, UV and mechanical impact

- Required IP or NEMA rating and any pressure or explosion protection requirements

This step determines the necessary material class, sealing concept and mechanical robustness.

Identify process interface and form factor

Next, define how the sensor will connect to the target environment:

- Thread size, flange type or other process connections

- Available installation space and preferred direction of cable exit

- Need for specific shapes such as cylindrical, rectangular or probe-type housings

Form factor constraints sometimes lead to the choice of specific standard housing families, simplifying procurement and assembly.

Match material properties to measurement needs

Finally, align material choice to the sensing principle and required accuracy:

- Temperature sensors may require metallic housings for fast response.

- Magnetic and inductive sensors must avoid materials that disturb magnetic fields in critical regions.

- Optical sensors need transparent, low-scatter windows with stable optical properties.

In complex applications, validation testing under representative conditions is recommended to confirm that the housing supports the intended sensor performance over the full lifetime.

FAQ: Sensor Housings

What IP rating should I choose for a sensor in a washdown area?

For washdown areas where equipment is regularly cleaned with water jets, a sensor housing with at least IP65 or IP66 is typically required. If high-pressure or high-temperature cleaning is used, IP69 is recommended. In addition to the IP rating, the housing material and seals must be resistant to cleaning agents and disinfectants used in the facility. Food and beverage environments often combine IP69 with stainless steel housings and hygienic design features.

When should I use a stainless steel sensor housing instead of plastic?

Stainless steel housings are appropriate when high mechanical strength, corrosion resistance or hygienic design are required. Typical cases are sensors in food processing, chemical plants, marine environments and high-temperature processes. Plastic housings can be sufficient in less demanding environments, such as indoor automation and building applications, where chemical exposure is limited and mechanical stresses are moderate. If in doubt, stainless steel often provides a broader safety margin but at higher cost and weight.

How do sensor housings affect temperature measurement response time?

The housing material, wall thickness and geometry all influence how quickly heat reaches the temperature sensor element. Metallic housings with thin walls and good contact to the medium enable faster response than thick-walled or plastic housings. Thermowells and protective sleeves add thermal mass and reduce heat transfer, increasing response time compared to direct immersion. When designing temperature measurements, it is important to consider the required response time and select a housing that provides adequate protection without introducing excessive thermal lag.

Can I use the same sensor housing indoors and outdoors?

A housing suitable for indoor use is not automatically suitable for outdoor environments. Outdoor use introduces exposure to UV radiation, rain, temperature extremes and often salt or pollution. For outdoor applications, select housings with adequate IP rating (typically IP65 or higher), UV-stable materials and corrosion-resistant fasteners. Some indoor-rated plastics can embrittle or discolor under sunlight, and indoor sealing concepts may not tolerate repeated wetting and drying cycles. Always verify that the housing is explicitly approved for outdoor use.