Hastelloy C-276 is a widely used nickel-molybdenum-chromium alloy known for its outstanding resistance to a broad range of corrosive media. Correctly deciding when to specify this alloy in part design is critical for safety, reliability, and lifecycle cost. This page explains the technical basis for choosing Hastelloy C-276, performance parameters, design criteria, and practical guidelines so that engineers and designers can justify its use with confidence.

What Is Hastelloy C-276

Hastelloy C-276 (UNS N10276, ISO NiMo16Cr15W) is a wrought corrosion-resistant alloy with a nickel base, substantial molybdenum and chromium additions, and a small tungsten addition. It was developed to withstand a wide range of severely corrosive environments, especially where both oxidizing and reducing species are present, or where process conditions are variable and not easily controlled.

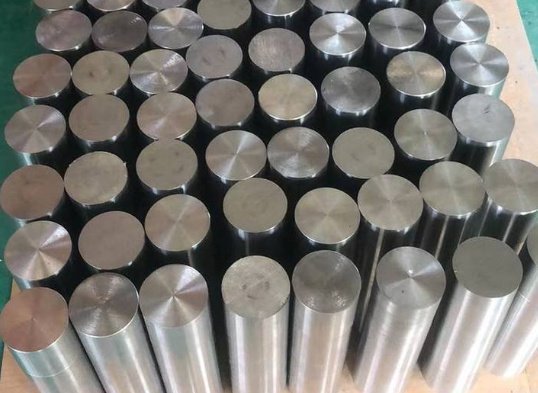

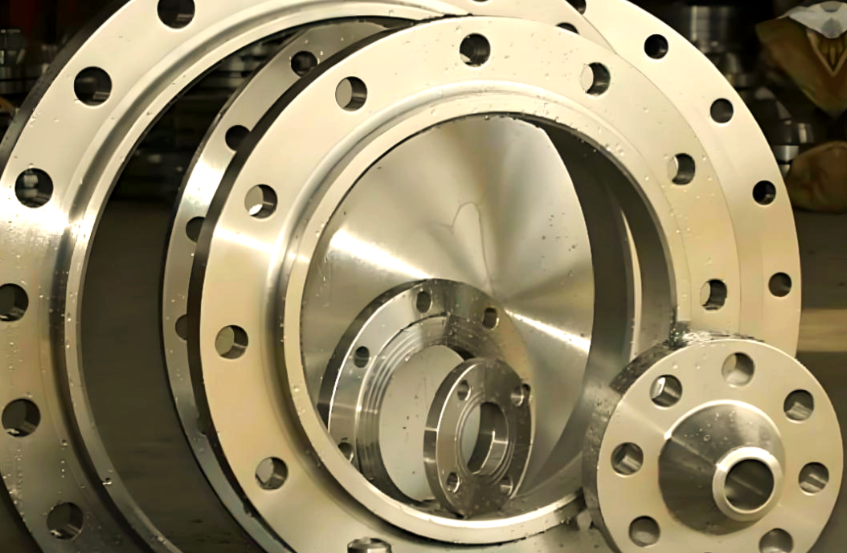

The alloy is supplied in various product forms, including plate, sheet, strip, bar, forging stock, pipe, tube, fittings, and welding products. It is typically used in the solution-annealed condition to obtain optimum corrosion resistance and good formability.

Chemical Composition and Key Properties

The composition of Hastelloy C-276 is tightly controlled to balance corrosion resistance, mechanical properties, and fabrication characteristics.

| Element | Content (wt%) |

|---|---|

| Nickel (Ni) | Balance (approx. 57 min) |

| Molybdenum (Mo) | 15.0–17.0 |

| Chromium (Cr) | 14.5–16.5 |

| Iron (Fe) | 4.0–7.0 |

| Tungsten (W) | 3.0–4.5 |

| Cobalt (Co) | 2.5 max |

| Manganese (Mn) | 1.0 max |

| Vanadium (V) | 0.35 max |

| Silicon (Si) | 0.08 max |

| Carbon (C) | 0.01 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

Key characteristics of this composition include:

- High nickel content for overall corrosion resistance and structural stability.

- High molybdenum for resistance to pitting and crevice corrosion in reducing and chloride-bearing environments.

- Chromium for resistance to oxidizing media and formation of stable passive films.

- Tungsten for additional resistance in some highly reducing environments.

- Very low carbon and silicon to minimize carbide and intermetallic precipitation during welding and heat exposure.

Mechanical Properties and Temperature Limits

Hastelloy C-276 offers moderate to high strength compared with austenitic stainless steels, combined with good ductility. Typical minimum room-temperature mechanical properties for plate in the solution-annealed condition are:

| Property | Typical Value | Notes |

|---|---|---|

| Ultimate tensile strength | ~ 690 MPa (100 ksi) | Plate, solution annealed |

| 0.2% yield strength | ~ 283 MPa (41 ksi) | Plate, solution annealed |

| Elongation (50 mm gauge length) | ~ 40–45% | Good ductility |

| Hardness | Typically ≤ 95 HRB | Depends on product and condition |

Allowable design stresses are defined in various pressure vessel codes and standards such as ASME Boiler and Pressure Vessel Code for specific product forms and temperatures. In general terms:

- Hastelloy C-276 is commonly used up to approximately 400–425 °C in many corrosive service applications where both corrosion resistance and mechanical properties are critical.

- At higher temperatures (up to around 600 °C in certain conditions), environmental compatibility and code limits must be evaluated carefully on a case-by-case basis.

At low temperatures, the alloy retains good toughness and is used in some cryogenic applications, although that is less common than its use in hot, corrosive service.

Corrosion Resistance: Where the Alloy Excels

The main reason to specify Hastelloy C-276 is its corrosion resistance in severe conditions. It performs well in environments that attack stainless steels, duplex stainless steels, and many nickel alloys.

Typical corrosion resistance attributes include:

Resistance to oxidizing and reducing media at the same time. Many process streams contain both oxidizing agents (such as ferric ions, nitric acid, dissolved oxygen) and reducing agents (such as hydrogen, sulfides, hydrochloric acid). Hastelloy C-276 is designed to handle this combination better than many alternative alloys.

High resistance to localized corrosion:

- Very good resistance to pitting in chloride-bearing media.

- Excellent resistance to crevice attack in tight geometries and in the presence of stagnant solutions.

- Good resistance to stress corrosion cracking in many chloride-containing environments where stainless steels may crack.

Environments where Hastelloy C-276 is often selected include:

- Strong chloride-bearing acids such as hydrochloric acid over a wide concentration and temperature range.

- Mixed acid systems including chlorides and oxidizing components.

- Sour gas (H2S) environments where sulfide stress cracking is a concern.

- Polluted seawater or brines with oxidizing species or high temperature.

- Wet chlorine gas, hypochlorites, and chlorine dioxide environments.

Before specification, designers should always consult authoritative corrosion data for the expected composition, temperature, flow regime, and impurities of the process fluid. Corrosion rates are highly dependent on these variables.

Typical Service Environments and Compatibility

Hastelloy C-276 is often used in circumstances where process conditions are difficult to control or may change over time. Examples include:

- Batch reactors where different chemistries are processed through the same equipment.

- Waste treatment systems receiving variable effluent quality.

- Heat exchangers exposed to both process side and utility side fluids that may be aggressive.

- Off-gas scrubbers dealing with corrosive condensates.

General compatibility profile:

Frequently suitable for:

- Hydrochloric acid across a broad concentration range and up to moderate-to-high temperatures, depending on impurities.

- Sulfuric acid in moderately strong concentrations with chloride impurities.

- Phosphoric acid contaminated with chlorides and fluorides used in fertilizer and phosphoric acid production.

- Acetic and formic acids in the presence of chlorides.

- Wet chlorine, chlorine dioxide, and hypochlorite solutions under controlled conditions.

Requires careful evaluation for:

- Strong oxidizing media at high temperatures, such as hot, concentrated nitric acid or fuming oxidizing mixtures.

- Molten salts and some high-temperature gas environments where other alloys or ceramics may be preferable.

In borderline environments, corrosion testing using representative process fluids and conditions is recommended to confirm expected alloy performance.

Design Criteria: When Hastelloy C-276 Is Justified

Hastelloy C-276 is significantly more expensive than common stainless steels and even many other nickel alloys. It is therefore typically reserved for applications where lesser materials cannot meet performance requirements. Situations where specifying this alloy is technically justified include:

1) Severe corrosion conditions with high consequence of failure:

- Equipment containing highly toxic, flammable, or otherwise hazardous fluids where through-wall corrosion could have serious safety or environmental consequences.

- Critical infrastructure with long design life requirements and limited accessibility for maintenance or replacement.

2) Mixed oxidizing and reducing environments:

- Processes where the chemical composition varies between reducing and oxidizing conditions, making it difficult to select materials optimized for only one category.

- Plants where unexpected upset conditions, contamination, or concentration swings may occur.

3) Localized corrosion risk:

- Components subjected to stagnant zones, crevices, or deposits where localized attack is more likely than uniform corrosion.

- Highly aerated chloride solutions in which pitting and crevice corrosion of stainless steels is expected.

4) Stress corrosion cracking concerns:

- Service where austenitic stainless steels might experience chloride stress corrosion cracking, particularly at moderate temperatures and in environments combining tensile stress and chlorides.

- Equipment operating under sustained stress, vibration, or thermal cycling in aggressive media.

5) Limited availability of alternative proven materials:

- Applications where data and field experience clearly demonstrate the reliability of Hastelloy C-276, but alternative alloys do not have equivalent track records in the specific environment.

Comparison with Stainless Steels and Other Alloys

To decide whether Hastelloy C-276 is appropriate, it is useful to compare it with more common alloys in terms of corrosion performance, mechanical properties, and cost implications.

Versus austenitic stainless steels (e.g., 304, 316, 904L):

- Hastelloy C-276 offers much higher resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking.

- Stainless steels are adequate for mildly to moderately corrosive environments at lower temperatures and are much more economical.

- When stainless steel corrosion rates exceed acceptable limits or localized corrosion is anticipated, Hastelloy C-276 becomes a prime candidate.

Versus duplex and super duplex stainless steels:

- Duplex grades can offer improved pitting resistance over standard stainless steels but may still be vulnerable in strongly reducing acids or mixed oxidizing-reducing environments.

- Hastelloy C-276 generally outperforms duplex grades in severe acid service but at a cost premium.

Versus other nickel alloys:

- Nickel-copper alloys (e.g., Monel) provide good resistance in some reducing environments but are generally weaker in strong oxidizing environments than Hastelloy C-276.

- High-chromium nickel alloys provide good oxidation resistance but may not match the localized corrosion resistance of Hastelloy C-276 in chloride-rich reducing media.

- Alternative corrosion-resistant nickel alloys (such as other Hastelloy grades or Inconel derivatives) may be preferred for specific oxidizing environments or higher temperature ranges; detailed comparison of corrosion data is essential.

Part Types and Applications Where C-276 Is Commonly Specified

Hastelloy C-276 is used across various industries and component types, such as:

- Chemical process equipment

- Reactors, vessels, and columns handling aggressive chemistries.

- Agitators, baffles, and internals where crevice corrosion can occur.

- Piping, elbows, and manifolds for corrosive transfer lines.

- Heat transfer equipment

- Shell-and-tube heat exchangers where either shell side or tube side is highly corrosive.

- Condenser tubes in chlorinated seawater or brine service.

- Pollution control and scrubber systems

- Absorber and scrubber internals for flue-gas treatment in power and waste incineration plants.

- Stack liners and ducting exposed to acidic condensates.

- Oil, gas, and petrochemical

- Components exposed to sour gas (H2S-containing) streams.

- Downhole equipment in severely corrosive reservoirs (where design codes allow).

- Pharmaceutical, biotech, and food processing

- Equipment exposed to aggressive cleaning or sterilization chemicals, especially where contamination or downtime is critical.

In part design, Hastelloy C-276 is specified for components such as pumps, valves, fasteners, clamps, bellows, flexible couplings, spray nozzles, and instrumentation fittings when the service environment requires higher corrosion resistance than stainless steel.

Design Considerations for Using Hastelloy C-276

When incorporating Hastelloy C-276 into a part design, several practical considerations should be addressed to achieve optimal performance and cost-effectiveness.

Wall thickness and corrosion allowance:

- Because the alloy is often chosen for severe service, designers may be tempted to apply large corrosion allowances. However, the high corrosion resistance often allows small allowances, especially where corrosion rates are well documented.

- Modest corrosion allowances can reduce weight and cost while maintaining sufficient safety margins.

Geometric features:

- Avoid dead legs, tight crevices, and areas where stagnant flow can occur, even though the alloy is resistant to crevice corrosion; minimizing such features improves overall reliability.

- Consider smooth radii and adequate drainage to reduce the risk of localized attack.

Connections and joints:

- Where possible, use welded construction instead of flanged joints to minimize leak paths and crevices.

- If disassembly is required, design flanges with gasket materials compatible with the service environment and with the thermal expansion behavior of the alloy.

Support and reinforcement:

- Mechanical strength is sufficient for many pressure-containing parts, but code-based allowable stresses should be used to determine required thicknesses, especially for pressure vessels and piping.

- In cyclic loading or vibration environments, consider fatigue performance and avoid sharp corners or stress concentrators.

Fabrication and Machining Guidelines

Hastelloy C-276 is workable but requires attention to its work-hardening and machining characteristics. Including fabrication considerations early in the design can prevent production delays and excessive costs.

Forming:

- The alloy can be cold formed with appropriate equipment; however, it work-hardens more rapidly than carbon steel or austenitic stainless steel.

- Operations such as bending, deep drawing, or spinning may require intermediate annealing to restore ductility.

- Hot working is typically carried out in the range recommended by product suppliers, followed by rapid cooling to maintain corrosion resistance.

Machining:

- Use carbide tools with positive rake angles and rigid setups.

- Apply low cutting speeds, moderate feeds, and generous cutting fluids to control heat and tool wear.

- Because of work-hardening, avoid dwelling or rubbing the tool on the material; keep tools sharp and use consistent, sufficient feed.

Cutting and shaping:

- Plasma cutting, waterjet cutting, and laser cutting are commonly used for plate and sheet.

- Thermal cutting operations should be followed by appropriate finishing where surface contamination or heat-affected zones might influence corrosion behavior.

Welding and Heat Treatment in Part Design

Hastelloy C-276 is designed to be weldable with minimal risk of sensitization or intergranular corrosion because of its low carbon and silicon content. This makes it suitable for complex welded assemblies used in aggressive environments.

Welding processes:

- Gas tungsten arc welding (GTAW / TIG), gas metal arc welding (GMAW / MIG), and shielded metal arc welding (SMAW) are commonly used.

- Matching filler metals (e.g., filler wires or electrodes based on C-276 composition) should be used to maintain corrosion resistance across welds.

- Proper shielding gas selection and joint preparation are essential to avoid contamination and porosity.

Heat treatment:

- The standard heat treatment for Hastelloy C-276 is solution annealing followed by rapid quenching.

- After heavy cold work or forming, solution annealing may be required to optimize corrosion resistance and mechanical properties, depending on application requirements.

- Postweld heat treatment is generally not required for corrosion resistance, but stress-relief may be considered in special cases, subject to corrosion and mechanical property evaluation.

Designers should ensure weld access is adequate, specify acceptable weld procedures, and consider non-destructive examination methods when the consequences of weld defects are high.

Surface Finish, Cleaning, and Maintenance Considerations

Although Hastelloy C-276 is very corrosion resistant, surface condition can influence performance, particularly in environments prone to localized corrosion or fouling.

Surface finish:

- Smoother surfaces (e.g., polished or fine-ground) typically exhibit better resistance to pitting and are easier to clean.

- For process equipment, specifying a suitable surface roughness (e.g., Ra value) can help reduce deposit buildup and facilitate cleaning.

Cleaning and passivation:

- Contaminants such as free iron, shop dirt, or foreign metal particles can initiate corrosion; thorough cleaning after fabrication is recommended.

- Chemical cleaning procedures should be selected to avoid overly aggressive media that are not compatible with the alloy.

Maintenance:

- Even when using this alloy, periodic inspection is prudent in critical service, especially in weld regions, crevices, and locations prone to solids deposition.

- For equipment where internal access is limited, consider integrating monitoring features like corrosion coupons, probes, or inspection ports in the design.

Cost, Material Availability, and Procurement

Hastelloy C-276 is considered a premium material. In part design, cost considerations include raw material, fabrication, inspection, and potential downtime or replacement costs if lesser materials fail.

Economic justification factors:

- Longer equipment life in severe service, reducing replacement frequency.

- Improved reliability in safety-critical or production-critical components where failure would cause extended shutdowns.

- Reduced need for corrosion allowances or cladding in some designs, possibly offsetting raw material cost.

Availability:

- C-276 is widely available from major suppliers in many product forms, but specific sizes, thicknesses, or shapes may have longer lead times.

- For large or complex parts, early coordination with suppliers helps ensure that raw material and welding consumables are available in the required timeframe.

Procurement recommendations:

- Specify recognized specifications (e.g., ASTM and UNS designations) and required condition (e.g., solution-annealed).

- Include requirements for traceability, material test reports, and, when necessary, additional testing such as corrosion tests or non-destructive examination.

Standards, Codes, and Specification Language

When defining Hastelloy C-276 in part drawings, purchase specifications, or engineering standards, it is important to use correct designations and reference applicable standards.

Common designations:

- UNS: N10276

- Trade name: Hastelloy C-276 (note that “Hastelloy” is a registered trademark; generic descriptions may be used where required).

- ISO material number: approximately NiMo16Cr15W (specific designation may vary by standard).

Typical product standards (examples, depending on region and product form):

- ASTM product standards for plate, sheet, strip, bar, pipe, and fittings.

- ASME Boiler and Pressure Vessel Code for allowable stresses and code case usage in pressure-containing equipment.

Specification practices:

- On drawings, clearly state material as “UNS N10276, solution annealed,” along with applicable product standards and any additional testing requirements.

- For welds, specify filler material type (e.g., matching alloy) and reference approved welding procedures.

- Include acceptable heat treatment and surface finish requirements where these affect performance.

Practical Triggers for Choosing Hastelloy C-276 in Design

To summarize the engineering perspective, you should strongly consider specifying Hastelloy C-276 when several of the following conditions apply to your part design:

- The service environment involves high chlorides, strong acids, or mixtures of oxidizing and reducing species.

- Conventional stainless steels or duplex steels have shown unacceptable corrosion rates, pitting, or cracking in similar service.

- Failure of the part would have serious health, safety, environmental, or economic consequences.

- Process conditions are variable or not tightly controlled, making material selection based on narrowly defined conditions risky.

- Maintenance access is limited, replacement downtime is costly, or very long service life is required.

- Design codes and past operational data support Hastelloy C-276 as a proven solution in comparable equipment and environments.

By evaluating these criteria and aligning them with corrosion data, codes, and lifecycle costs, engineers can decide when the additional investment in Hastelloy C-276 is justified and will yield reliable performance in demanding applications.