Hastelloy C-276 and titanium alloys are widely used in aggressive environments where stainless steels and conventional alloys fail. Both material families provide high corrosion resistance and good mechanical properties, but they differ significantly in composition, density, cost structure, fabrication requirements, and long‑term lifecycle behavior. This comprehensive comparison focuses on cost, performance, and lifecycle aspects to support technically sound material selection for industrial equipment and components.

Fundamental Overview of Hastelloy C-276 and Titanium Alloys

Hastelloy C-276 is a nickel‑molybdenum‑chromium alloy with tungsten additions, designed for broad resistance to severe corrosion, including pitting, crevice attack, and stress corrosion cracking in both oxidizing and reducing environments. Titanium alloys are based on titanium as the main element, often alloyed with aluminum, vanadium, and other elements to tune strength, weldability, and corrosion behavior.

Common titanium alloys used in industrial and marine environments include commercially pure (CP) grades such as Grade 2 and alpha‑beta alloys such as Grade 5 (Ti‑6Al‑4V). These alloys offer excellent specific strength and outstanding corrosion resistance in chloride media and many oxidizing environments, though their behavior differs from Hastelloy C‑276 in reducing acids and high‑temperature conditions.

Chemical Composition and Alloy Classification

The core difference between the two materials starts with their chemical composition and alloy system. Hastelloy C‑276 belongs to the Ni‑Mo‑Cr superalloy family, while titanium alloys are lightweight reactive metals.

| Alloy | Ni | Mo | Cr | Fe | W | Co | Ti | Al | V |

|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C-276 | Balance (~55–65) | 15–17 | 14.5–16.5 | 4–7 | 3–4.5 | ≤2.5 | – | – | – |

| CP Titanium Grade 2 | – | – | – | ≤0.3 | – | – | Balance | ≤0.1 | – |

| Ti-6Al-4V Grade 5 | – | – | – | ≤0.4 | – | – | Balance | 5.5–6.75 | 3.5–4.5 |

Key implications of these compositions include:

- Hastelloy C‑276 achieves its corrosion resistance primarily through the synergy of nickel, molybdenum, and chromium, with tungsten enhancing resistance in certain media.

- Titanium alloys rely on a stable, tightly adherent titanium dioxide (TiO₂) passive film for corrosion protection. Alloying elements such as aluminum and vanadium are mainly used to refine mechanical properties and phase balance.

- The presence of heavy elements (Ni, Mo, W) makes Hastelloy C‑276 dense and relatively heavy compared to titanium, which influences weight‑sensitive applications and transportation costs.

Mechanical Properties and Structural Performance

Hastelloy C‑276 and titanium alloys provide distinct mechanical property profiles that influence design thickness, weight, and allowable stress at different temperatures.

Room Temperature Mechanical Properties

Typical room temperature properties are as follows (values are indicative and may vary by product form and specification):

- Hastelloy C‑276 (plate, solution annealed):

- Tensile strength: ~690–800 MPa

- Yield strength (0.2% offset): ~280–355 MPa

- Elongation: typically ≥40%

- Hardness: approximately 200 HB - CP Titanium Grade 2:

- Tensile strength: ~345–485 MPa

- Yield strength: ~275–410 MPa

- Elongation: ~20–30% - Ti‑6Al‑4V Grade 5 (annealed):

- Tensile strength: ~895–930 MPa

- Yield strength: ~825–880 MPa

- Elongation: ~10–14%

In structural terms:

- CP titanium offers moderate strength but excellent ductility and toughness at low density, leading to very high specific strength.

- Ti‑6Al‑4V often exceeds the strength of Hastelloy C‑276 on a per‑weight basis, but its corrosion behavior is more environment‑dependent.

- Hastelloy C‑276 combines good absolute strength with superior uniform corrosion and localized corrosion resistance in many chemicals, allowing thinner walls in some demanding chemical environments where titanium could be at risk.

High Temperature Mechanical Behavior

At elevated temperatures, both materials exhibit reduced strength. Hastelloy C‑276 is typically used up to around 400–425°C in many codes for pressure‑containing equipment, with some non‑pressure parts used at higher temperatures depending on environment. Titanium alloys such as Grade 2 and Grade 5 are often applied up to approximately 300–350°C for structural uses, with allowable stresses decreasing markedly above these temperatures.

In high temperature, highly corrosive chemical environments, Hastelloy C‑276 generally offers a more favorable combination of corrosion resistance and mechanical stability, while titanium alloys are more often selected for moderate temperatures combined with weight‑critical requirements.

Corrosion Resistance in Different Environments

Corrosion behavior is one of the principal drivers when comparing Hastelloy C‑276 with titanium alloys. Their performance varies depending on media, temperature, concentration, and flow conditions.

Acids and Mixed Chemical Media

Hastelloy C‑276 is designed for broad resistance in both oxidizing and reducing acids, whereas titanium is predominantly resistant in oxidizing conditions and may be vulnerable in certain reducing acids and halide‑containing environments.

Typical trends include:

- Hydrochloric acid (HCl):

- Hastelloy C‑276 exhibits excellent resistance over a wide range of concentrations and temperatures, significantly outperforming most stainless steels.

- Titanium alloys may suffer from rapid corrosion or hydrogen pickup, especially at elevated temperatures or high chloride activity. - Sulfuric acid (H₂SO₄):

- Hastelloy C‑276 offers very good resistance in many concentration‑temperature combinations, particularly in contaminated or aerated solutions.

- CP titanium has good resistance in some dilute sulfuric acid environments but can be less reliable at higher temperatures or concentrations, especially when reducing conditions prevail. - Phosphoric acid and mixed fertilizer acids:

- Hastelloy C‑276 is commonly used in equipment handling wet‑process phosphoric acid containing chlorides and fluorides.

- Titanium can be used in certain purified or controlled‑impurity phosphoric acid services but may require careful evaluation when fluoride ions are present.

Chlorides, Seawater, and Brine

Both material systems are used extensively in chloride environments, but their behavior is not identical.

- Hastelloy C‑276:

- Very good resistance to pitting and crevice corrosion in many high‑chloride environments, even at elevated temperatures.

- Useful for hot brines, concentrated chlorides, and chemically complex solutions where mixed oxidizing and reducing species coexist. - Titanium alloys:

- CP titanium is highly resistant to seawater and many chloride solutions at ambient and moderate temperatures due to its stable passive film.

- Crevice corrosion can occur at elevated temperatures or under tight crevice conditions in hot seawater or chlorinated seawater.

- Titanium is typically an excellent choice for heat exchanger tubes, seawater cooling systems, and marine structures, particularly where weight reduction is beneficial.

Oxidizing vs Reducing Environments

The protective mechanisms differ:

- Hastelloy C‑276:

- Contains chromium for passivation in oxidizing environments and molybdenum for enhanced resistance in reducing media.

- Excels in mixed environments with both oxidizing and reducing species, as well as in media containing chlorides, sulfides, and other aggressive ions. - Titanium alloys:

- Depend on the TiO₂ film, which is very stable under oxidizing conditions but can be compromised under strongly reducing conditions or in the presence of certain halogenated organic compounds.

- In strongly reducing acids without oxidizing species, titanium can experience higher corrosion rates and hydrogen embrittlement risks.

Fabrication, Welding, and Machinability

Fabrication characteristics have direct impact on component cost, production lead time, and achievable geometry. Hastelloy C‑276 and titanium alloys each require specific handling and expertise.

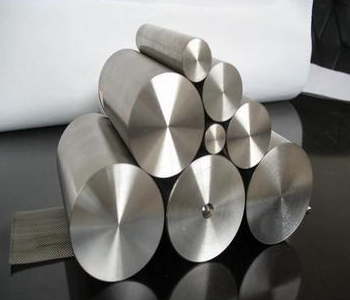

Forming and Machining

Hastelloy C‑276:

- Density: approximately 8.9 g/cm³, leading to heavier components.

- Machining: similar to other high‑alloy nickel materials; requires rigid tooling, lower cutting speeds, and adequate coolant to manage work hardening and heat generation.

- Cold forming: feasible but requires higher forces than stainless steel; springback is significant and must be compensated in tooling.

Titanium alloys:

- Density: approximately 4.5 g/cm³, about half that of Hastelloy C‑276, facilitating lighter components and easier manual handling.

- Machining: more challenging in some aspects due to low thermal conductivity and high chemical reactivity at elevated temperatures. Requires sharp tools, controlled cutting speeds, high‑pressure coolant, and attention to avoid tool wear and galling.

- Cold forming: CP titanium grades are relatively formable, but higher strength alloys such as Ti‑6Al‑4V require more force and sometimes elevated temperature forming.

Welding Characteristics

Welding is a critical consideration for pressure vessels, piping, and complex fabrications.

Hastelloy C‑276:

- Generally weldable by gas tungsten arc welding (GTAW/TIG), gas metal arc welding (GMAW/MIG), shielded metal arc welding (SMAW), and other common processes using matching filler metals.

- Low carbon content minimizes carbide precipitation, improving resistance to weld‑affected corrosion.

- Requires attention to heat input and interpass temperatures to maintain corrosion resistance and avoid distortion.

Titanium alloys:

- Highly sensitive to contamination by oxygen, nitrogen, hydrogen, and other gases at elevated temperature.

- Require stringent shielding with high‑purity inert gas (typically argon), including weld pool, hot weld metal, and heat‑affected zone, often using trailing shields and back‑purge systems.

- When procedures are properly controlled, high‑quality welds with good mechanical properties and corrosion resistance are achievable.

Welded construction in titanium typically involves more rigorous process control and operator training than Hastelloy C‑276. This can offset some of titanium’s raw material cost advantages in certain geometries or production volumes.

Cost Structure and Economic Comparison

Cost evaluation must consider more than just the price per kilogram. Raw material price, density, fabrication complexity, required thickness, inspection requirements, and expected service life all influence total expenditure.

Raw Material and Density Effects

Hastelloy C‑276 is generally more expensive per kilogram than many titanium grades due to high nickel, molybdenum, and tungsten content. However, its higher density means that cost per unit volume can be significantly higher compared to titanium.

Titanium alloys often have a lower or comparable cost per kilogram depending on market conditions, but because of their much lower density, the cost per volume and cost per component can differ substantially. In components where design is driven by stiffness and allowable stress, titanium’s low density and high specific strength may result in lower mass and potentially lower raw material cost for the same mechanical function.

Fabrication and Processing Costs

Fabrication costs can narrow or widen the gap between the two materials:

- Hastelloy C‑276:

- Machining and forming are demanding but use familiar practices used for other nickel alloys.

- Welding is relatively straightforward with appropriate procedures; process control is important but less extreme than for titanium.

- Tooling wear and lower machining productivity add cost compared to carbon steel or 300‑series stainless steel. - Titanium alloys:

- Require special attention during machining due to heat buildup, chip control, and tool life.

- Welding demands strict shielding, clean environments, precise control of gas purity, and careful handling to avoid contamination.

- Set‑up costs, specialized fixtures, and quality assurance requirements may be higher, particularly for critical applications.

In some cases, titanium’s lower density reduces shipping, handling, and support structure costs, which can be relevant in large assemblies or offshore installations.

Lifecycle and Maintenance Considerations

Lifecycle assessment includes initial procurement, installation, inspection, repair, downtime, and eventual replacement or recycling. The choice between Hastelloy C‑276 and titanium alloys often hinges on anticipated service life and maintenance strategies in a specific environment.

Service Life in Aggressive Environments

In chemical process industries, Hastelloy C‑276 is frequently selected for units that encounter varied feedstocks, impurities, or upset conditions. Its broad resistance reduces the likelihood of unexpected corrosion damage when operating conditions deviate from nominal. This can extend service life and reduce unplanned shutdowns.

Titanium alloys, especially CP grades, deliver very long service life in properly defined environments such as clean seawater, certain oxidizing acids, and many chloride solutions at moderate temperatures. When service conditions remain within carefully verified limits, titanium equipment can operate for decades with minimal corrosion‑related degradation.

Maintenance, Inspection, and Repair

Regular inspection regimes (thickness measurement, surface examination, NDT of welds) apply to both materials, but specific degradation modes differ.

- Hastelloy C‑276:

- Typically inspected for uniform metal loss, localized corrosion, and weld integrity.

- If attack occurs, it is often evident as localized pitting or general thinning; repair welding with matching filler is usually feasible. - Titanium alloys:

- Inspected for signs of crevice corrosion in seawater systems, hydrogen‑related effects in certain chemical environments, and erosion‑corrosion in high‑velocity flows with entrained solids.

- Repair welding is possible but must follow strict contamination control and may require specialized facilities, particularly for pressure‑containing components.

Downtime costs may dominate material and fabrication costs in some industries. Choosing a material that minimizes unexpected failures and simplifies repair logistics is often more important than small differences in initial purchase price.

Weight, Structural Design, and System Integration

Density and specific strength affect not only individual components but also the entire system, including foundations, supports, transport, and installation.

Hastelloy C‑276’s higher density results in heavier vessels and piping for a given wall thickness. This is acceptable for many fixed, land‑based chemical and pharmaceutical plants where structural support is not a primary constraint. However, for offshore platforms, shipboard systems, and aerospace‑adjacent applications, weight reduction can substantially lower overall system cost.

Titanium alloys excel where weight is critical. Heat exchangers with titanium tubes can achieve both corrosion resistance and weight savings, reducing support structure size and easing installation. In rotating equipment, such as impellers in seawater or chloride solutions, titanium’s low density reduces rotational inertia and bearing loads, which can influence equipment sizing and energy consumption.

Industry Applications and Typical Use Cases

While both materials serve corrosion‑resistant functions, their typical application domains differ, reflecting their inherent strengths.

Chemical Processing and Refining

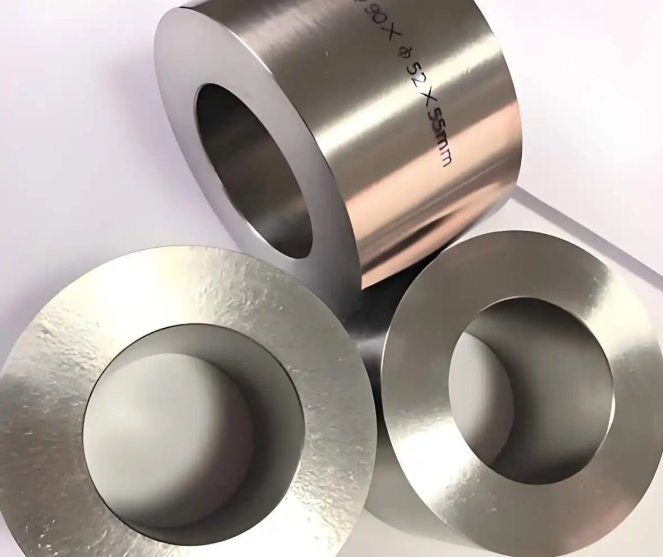

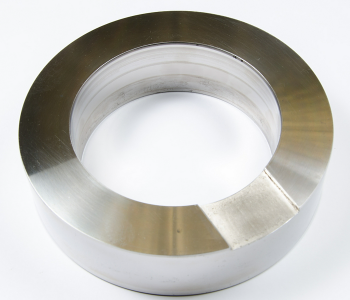

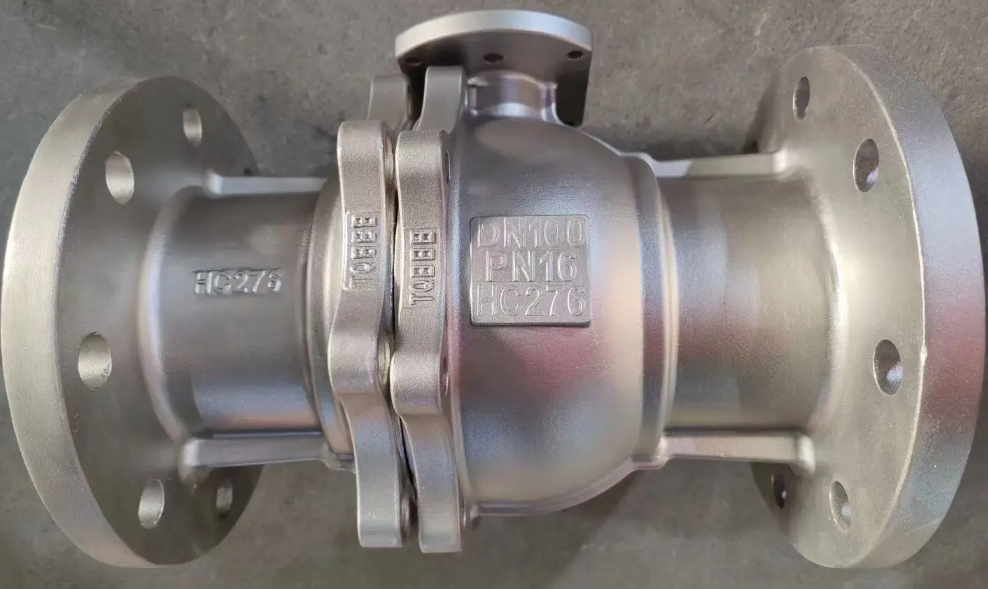

Hastelloy C‑276 is widely used in:

- Reactors and autoclaves for mixed acid service.

- Scrubbers, absorbers, and ducting for flue gas cleaning systems where condensates may be acidic and chloride‑bearing.

- Piping, valves, and pumps in processes involving hydrochloric acid, sulfuric acid, phosphoric acid, and wet chlorine.

- Components subjected to off‑spec or upset conditions where chemical compositions vary and impurities are present.

Titanium alloys in chemical processing are more common in:

- Equipment handling oxidizing chlorine‑bearing solutions at controlled temperatures.

- Certain bleaching and chlorination stages in pulp and paper production.

- Heat exchangers handling seawater or cooling waters with controlled chemistry.

Marine, Offshore, and Desalination

Titanium alloys, especially Grade 2, are extensively used in:

- Seawater‑cooled heat exchangers, condensers, and coolers.

- Desalination plants (multi‑stage flash, multi‑effect distillation, and RO systems) for tubing and high‑pressure components exposed to seawater or brine.

- Offshore structures and components where weight reduction and seawater corrosion resistance are essential.

Hastelloy C‑276 is selected in marine and offshore contexts when:

- Seawater or produced water is combined with aggressive chemicals, sour gas (H₂S), or high temperature conditions.

- Downhole tools, completion equipment, or subsea components encounter complex brine compositions with high chloride, CO₂, H₂S, and other corrosive species.

Power Generation and Environmental Systems

In power plants, environmental control systems, and waste treatment, material selection may shift between the two depending on specific process streams.

- Hastelloy C‑276 is often used in:

- Flue gas desulfurization (FGD) absorbers, reheaters, and associated piping in fossil fuel power plants.

- Components exposed to acidic condensates or mixed chloride/sulfate media at elevated temperatures. - Titanium is applied in:

- Condenser tubes in power plants that utilize seawater or brackish water cooling.

- Heat recovery systems where seawater corrosion resistance and low weight are advantageous.

Regulatory, Code, and Standards Considerations

Both Hastelloy C‑276 and titanium alloys are covered by various international standards and design codes, which influence allowable stresses, fabrication practices, and inspection requirements.

Common references include:

- ASTM material specifications (e.g., ASTM B575 for plate, B622 for pipe for Hastelloy C‑276; ASTM B265 for titanium plate, B338 for titanium tubes).

- ASME Boiler and Pressure Vessel Code (Section II materials, Section VIII design) providing allowable stresses and design rules for pressure equipment.

- ISO and EN standards for titanium and nickel alloys used in pressure equipment, piping, and marine applications.

Designers must confirm that selected product forms and thicknesses are code‑listed and that welding consumables and procedures are qualified accordingly. Code‑listed allowable stresses may differ from nominal strength values and have a direct impact on required wall thickness, hence affecting weight and cost.

Side-by-Side Summary of Key Attributes

| Attribute | Hastelloy C-276 | CP Titanium Grade 2 / Ti-6Al-4V (Generalized) |

|---|---|---|

| Alloy system | Ni-Mo-Cr-W superalloy | Alpha or alpha-beta titanium alloy |

| Density | ~8.9 g/cm³ (high) | ~4.5 g/cm³ (low) |

| Typical strength (room temperature) | Medium-high tensile, good ductility | Grade 2: medium; Grade 5: high strength |

| Primary corrosion strengths | Broad resistance in oxidizing + reducing environments, strong acids, mixed media | Excellent in seawater, many chlorides, oxidizing environments; more limited in some reducing acids |

| Welding | Good weldability, standard shielding practices | Requires stringent inert gas shielding and contamination control |

| Fabrication complexity | High relative to steels; typical for Ni alloys | High; demanding machining and welding practices |

| Weight-critical suitability | Less favorable due to high density | Very favorable; high specific strength |

| Typical industries | Chemical processing, refining, FGD, sour service | Marine, desalination, aerospace-adjacent, seawater systems |

| Lifecycle focus | Reliability under wide-ranging chemical conditions | Long life in well-defined, especially seawater/oxidizing environments with weight benefits |

Material Selection Considerations

Choosing between Hastelloy C‑276 and titanium alloys requires a systematic evaluation of process conditions and project priorities. Key aspects include:

- Corrosion environment:

- Identify all chemical species, impurities, temperature ranges, and potential upset conditions.

- Determine whether the environment is predominantly oxidizing, reducing, or mixed, and whether chlorides, fluorides, or sulfides are present. - Mechanical and thermal requirements:

- Establish operating and design pressures and temperatures.

- Evaluate allowable stress from relevant codes and assess potential thermal cycling, fatigue loading, and pressure transients. - Weight and geometry:

- Consider whether component weight affects structural supports, transport, or installation logistics.

- Assess whether high specific strength can be exploited through reduced wall thickness. - Fabrication capabilities:

- Confirm availability of experienced fabricators familiar with nickel alloys or titanium welding, as appropriate.

- Evaluate required inspection and acceptance criteria for welds and formed components. - Economic factors:

- Compare raw material cost, density, and required thickness to estimate material mass.

- Incorporate fabrication cost, expected service life, inspection intervals, and downtime cost in the lifecycle cost model.

In general terms, Hastelloy C‑276 tends to be favored for highly aggressive, chemically complex environments, especially in the chemical and petrochemical sectors. Titanium alloys are often preferred where seawater or chlorides are dominant, temperatures are moderate, and weight reduction provides tangible benefits, such as in heat exchangers, offshore systems, and desalination plants.

FAQ: Hastelloy C-276 and Titanium Alloys

Is Hastelloy C-276 more corrosion-resistant than titanium?

Hastelloy C‑276 generally offers broader corrosion resistance across a wider range of aggressive chemical environments compared to titanium, especially in strongly reducing acids, mixed acid systems, and high‑temperature chloride solutions. Titanium, particularly CP grades, provides excellent resistance in seawater, many chloride solutions, and oxidizing environments, but may be vulnerable in strongly reducing acids and certain halide‑containing media where Hastelloy C‑276 remains stable. The superior material depends on the specific environment; in many mixed or highly reducing chemical services, Hastelloy C‑276 is preferred, while in seawater‑dominated and weight‑sensitive systems, titanium is often the better choice.

Which is more cost-effective over the lifecycle: Hastelloy C-276 or titanium?

Lifecycle cost effectiveness depends on the specific application, environment, and operating strategy. Hastelloy C‑276 may have higher raw material cost per kilogram and higher density, but it can prevent premature failure in highly aggressive, variable chemical conditions and reduce unplanned downtime, which can outweigh higher initial expenditure. Titanium alloys, with lower density and high specific strength, can reduce component mass and structural requirements, often leading to cost advantages in seawater systems, offshore installations, and weight‑critical equipment. Where the environment is well characterized and within titanium’s corrosion envelope, titanium can provide very long service life with low maintenance. A rigorous lifecycle analysis considering corrosion allowance, expected service life, inspection and repair strategies, and downtime costs is necessary to determine which material is more economical for a given project.