4135 (AISI 4135) and 34CrMo4 (EN 1.7220) are closely related chromium‑molybdenum (Cr‑Mo) alloy steels widely used for medium‑to‑high strength, quenched-and-tempered engineering components. They combine good hardenability, strength, and toughness with reasonably good machinability, which makes them suitable for shafts, gears, fasteners, and critical automotive and machine‑building parts.

Overview of 4135 / 34CrMo4 Alloy Steel

4135 and 34CrMo4 belong to the family of low‑alloy Cr‑Mo steels. Their alloy design improves mechanical performance compared with plain carbon steels by providing:

- Higher hardenability for through‑hardening of thicker sections

- Improved strength and fatigue resistance after quenching and tempering

- Good toughness and impact resistance when properly heat treated

These steels are standardized in different systems but are used in similar applications. 4135 is typically referenced in North American standards, whereas 34CrMo4 is defined in EN standards in Europe and other regions.

Standards, Designations, and Product Forms

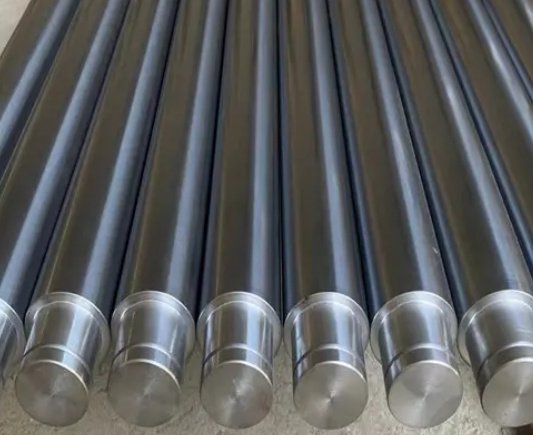

4135 / 34CrMo4 is supplied under various national and international standards and can be found in multiple product forms such as hot‑rolled bars, forged bars, tubes, and sometimes plates and rings.

| System / Region | Designation | Notes |

|---|---|---|

| UNS / AISI-SAE | AISI 4135, UNS G41350 | Common North American grade in the 41xx Cr‑Mo family |

| EN (Europe) | 34CrMo4, EN 1.7220 | Defined in EN 10083 for engineering steels |

| Germany (DIN / W.Nr.) | 34CrMo4, 1.7220 | Traditional Werkstoffnummer designation |

| China (GB) | 34CrMo4‑equivalent grades (e.g. 35CrMo) | Similar Cr‑Mo composition, local naming conventions |

| Japan (JIS) | SCM435 (close equivalent) | Often used interchangeably in similar applications |

Typical product forms include:

- Hot‑rolled and forged bars and billets for shafts, axles, and machine parts

- Hollow bars and mechanical tubing for cylinders, sleeves, and pressure parts

- Pre‑machined blanks for gears, flanges, and rings

Chemical Composition

4135 / 34CrMo4 is a low‑alloy steel with moderate carbon and additions of chromium and molybdenum. The composition is balanced to achieve reliable hardenability and strength after quench and temper treatment without excessive alloy cost.

| Element | Typical Range (EN 34CrMo4 style) | Typical Range (AISI 4135 style) | Function |

|---|---|---|---|

| C | 0.30 – 0.38 | 0.33 – 0.38 | Base hardness and strength |

| Si | ≤ 0.40 | 0.15 – 0.35 | Deoxidizer, contributes to strength |

| Mn | 0.60 – 0.90 | 0.60 – 0.90 | Improves hardenability and toughness |

| P | ≤ 0.025 | ≤ 0.030 | Impurity; should be low for toughness |

| S | ≤ 0.035 | ≤ 0.040 | Impurity; resulfurized variants increase machinability |

| Cr | 0.90 – 1.20 | 0.80 – 1.10 | Hardenability, wear resistance, strength |

| Mo | 0.15 – 0.30 | 0.15 – 0.25 | Tempering resistance, strength at section core |

| Ni | ≤ 0.30 (often residual) | ≤ 0.25 | Improves toughness (if present) |

| Cu | ≤ 0.30 | ≤ 0.35 | Residual; slight strength gain possible |

Exact limits vary with the standard and supplier, but the ranges above are representative. When ordering, the required standard (e.g. EN 10083‑3, ASTM, or specific OEM specification) should be clearly indicated.

Microstructure and Hardenability

In the delivered condition, 4135 / 34CrMo4 may be supplied normalized, soft annealed, or quenched and tempered, depending on the specification. The microstructure in each condition significantly influences machining behavior and mechanical properties.

Key microstructural characteristics include:

- Pearlitic‑ferritic structure in annealed or normalized state for good machinability

- Tempered martensite after quenching and tempering, providing a combination of strength and toughness

- Uniform hardness across the cross‑section for moderate diameters due to Cr and Mo enhanced hardenability

Typical effective hardening depth is adequate for many medium‑section shafts and gears. For very thick sections, process control (austenitizing temperature, quenching medium, and agitation) is important to avoid soft cores or excessive residual stresses.

Mechanical Properties

The mechanical properties of 4135 / 34CrMo4 depend strongly on the heat treatment condition, particularly the hardness level and corresponding tensile strength. Below are representative values; actual requirements are defined by standards or project specifications.

Room‑Temperature Mechanical Properties (Quenched and Tempered)

Typical properties for quenched and tempered 34CrMo4 at various hardness levels:

Approximate correlation between hardness and strength (room temperature):

- Hardness: 250 – 280 HB → Tensile strength Rm ≈ 800 – 900 MPa, yield strength Re ≈ 650 – 750 MPa, elongation A5 ≈ 14 – 18 %

- Hardness: 280 – 320 HB → Rm ≈ 900 – 1000 MPa, Re ≈ 750 – 850 MPa, A5 ≈ 12 – 16 %

- Hardness: 320 – 360 HB → Rm ≈ 1000 – 1100 MPa, Re ≈ 800 – 900 MPa, A5 ≈ 10 – 14 %

Typical impact toughness (Charpy V‑notch) for well‑processed material can range from about 30 to 60 J at room temperature, depending on strength level, cleanliness, and section size. Higher strength (higher hardness) generally reduces impact toughness.

Properties in Annealed and Normalized Conditions

For soft annealed or normalized 4135 / 34CrMo4, typical values might be:

- Hardness: approx. 180 – 220 HB

- Tensile strength Rm: approx. 600 – 750 MPa

- Good elongation and machinability, suitable for rough machining before final heat treatment

For components used without subsequent heat treatment, the mechanical properties must be checked against design requirements, especially for fatigue and shock loading.

Heat Treatment of 4135 / 34CrMo4

Heat treatment is central to achieving the desired balance of hardness, strength, and toughness. The steel responds well to standard heat treatment processes used for engineering steels.

Soft Annealing

Soft annealing is performed to reduce hardness and improve machinability and cold‑formability:

- Typical temperature: 680 – 720 °C

- Holding time: sufficient for full heating of the section and structure homogenization

- Cooling: usually controlled furnace cooling, e.g. 10 – 20 °C per hour down to approx. 600 °C, then air cooling

The resulting hardness is usually in the range of approximately 180 – 220 HB.

Normalizing

Normalizing is used to refine grain size, homogenize microstructure, and prepare material for subsequent quenching and tempering:

- Typical temperature: 860 – 900 °C

- Holding time: adequate for full austenitization (commonly 0.5 – 1 hour depending on section size)

- Cooling: air cooling in still air

Normalizing reduces segregation from hot working and reduces internal stresses. Hardness after normalizing is generally slightly higher than after soft annealing.

Quenching and Tempering

Quenching and tempering delivers the main working condition for 4135 / 34CrMo4 components. The procedure typically includes:

1) Austenitizing and Quenching

- Austenitizing temperature: approx. 830 – 870 °C

- Holding: sufficient to fully heat through the section and dissolve carbon in austenite

- Quenching media: oil quench is common; for small sections, polymer or water‑based quenchants may be used with careful control to limit distortion and cracking

After quenching, the structure becomes martensitic and brittle, requiring tempering before service.

2) Tempering

- Typical tempering temperatures: 450 – 650 °C

- Lower tempering temperatures (~450 – 500 °C) produce higher strength and hardness but lower toughness

- Higher tempering temperatures (~550 – 650 °C) reduce hardness and increase toughness and ductility

- Cooling after tempering: generally air cooling

A common practice is double tempering for highly stressed components to stabilize the microstructure and reduce residual stresses. Tempering temperature selection is based on required tensile strength or hardness and the service environment (e.g. risk of brittle fracture at low temperature).

Stress Relieving

Stress relieving heat treatment is often used after rough machining or welding to reduce residual stresses and minimize distortion in subsequent operations:

- Typical temperature: 500 – 650 °C, depending on the specified hardness range

- Holding time: usually 1 – 2 hours after achieving uniform temperature

- Cooling: slow cooling in still air; for more demanding dimensional stability, furnace cooling may be used

Surface Hardening (Carburizing, Nitriding, Induction)

Where high surface wear resistance is needed without losing a tough core, 4135 / 34CrMo4 can be surface hardened:

- Induction or flame hardening: localized heating followed by quenching to harden specific regions such as gear teeth or shaft journals

- Nitriding (for certain variants): formation of a hard nitride surface layer with minimal distortion

Carburizing is less common compared with lower‑carbon alloy steels, because 4135 already has moderate carbon content, but it may still be employed under specific design requirements.

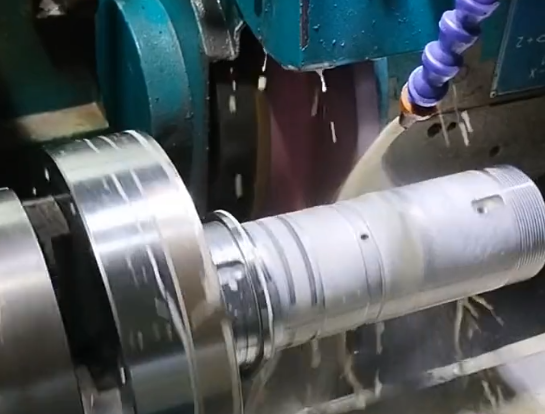

Machinability and Machining Guidelines

4135 / 34CrMo4 offers moderate to good machinability, especially in the annealed or normalized state. In high‑strength, quenched and tempered conditions, machining becomes progressively more difficult due to increased hardness and strength.

Machinability Characteristics

Relative machinability (compared to a 0.45% carbon steel at 100%) is often in the range of about 60 – 70% for annealed 4135 / 34CrMo4, though values depend on exact condition and sulphur content. Resulfurized variants exhibit improved chip breaking and slightly better tool life at the expense of some toughness.

Turning, Milling, and Drilling Recommendations

General machining guidelines for 4135 / 34CrMo4 include:

- Use the annealed or normalized condition for extensive rough machining and only then quench and temper to final properties

- Employ high‑quality carbide tools for medium to high‑production turning and milling; high‑speed steel (HSS) tools are possible but at lower cutting speeds

- Provide adequate coolant and chip evacuation to control temperature and avoid built‑up edge

As hardness increases above about 280 – 300 HB, cutting speeds should be reduced and tougher tool grades may be selected. For hardened surface regions (induction‑hardened), specialized hard‑turning techniques may be needed.

Typical Machining Pain Points and Considerations

Common issues encountered when machining 4135 / 34CrMo4 include:

- Tool wear and chipping in higher hardness ranges, particularly at interrupted cuts or unstable setups

- Risk of dimensional changes after final heat treatment if heat‑treatment distortion is not adequately anticipated

- Formation of long chips in some conditions if chip breakers and cutting parameters are not optimized

To mitigate these difficulties, process planning often separates rough machining (in softer condition) from finishing machining (after heat treatment with allowances), and may include intermediate stress relieving to maintain dimensional stability.

Weldability and Welding Procedures

4135 / 34CrMo4 is not a free‑welding structural steel, but it can be welded with appropriate precautions. The carbon and alloy content introduce sensitivity to hydrogen cracking and heat‑affected zone embrittlement if welding is not properly controlled.

Weldability Classification

These steels are generally considered to have limited weldability and require preheating and post‑weld heat treatment, especially for thick sections or highly restrained joints. Weldability is influenced by carbon equivalent (CE), which typically lies in a range that necessitates careful thermal management.

Recommended Welding Practices

- Preheating: common ranges are approx. 200 – 300 °C, depending on thickness and restraint level

- Interpass temperature: maintain within recommended limits (often similar to or slightly above preheat) to avoid excessive hardness and residual stresses

- Post‑weld heat treatment: stress relieving or full quench and temper may be required to restore mechanical properties and reduce residual stresses

- Use of low‑hydrogen welding consumables to minimize risk of hydrogen‑induced cracking

For critical components (such as pressure parts or safety‑relevant automotive components), welding should be approved and qualified by appropriate procedures, including weld procedure qualification records (WPQR) and non‑destructive testing of joints.

Formability, Forging, and Hot Working

4135 / 34CrMo4 has good hot workability and is widely forged into shafts, rings, and other shaped parts.

Forging Temperature Range

- Typical forging temperature: heating to approx. 1150 – 1200 °C

- Finish forging temperature: not lower than about 850 – 900 °C to maintain adequate ductility

- Cooling: usually controlled cooling in still air or in dry insulating materials, followed by normalizing or annealing

Overheating during forging can lead to grain coarsening, reducing toughness. After forging, a suitable heat treatment (often normalizing and then quenching and tempering) is applied to restore uniform and fine microstructure.

Cold Working and Bending

Cold forming of 4135 / 34CrMo4 is feasible in the annealed condition, but formability is reduced compared to low‑carbon structural steels due to higher strength. For operations like bending, drawing, or upsetting, attention is required to avoid cracking; moderate preheating (e.g. 150 – 250 °C) is sometimes used for critical cold‑working operations on thicker sections.

Surface Treatments and Wear Resistance

Surface treatment is often employed to enhance wear and fatigue resistance of 4135 / 34CrMo4 components without compromising a tough core.

Induction and Flame Hardening

Due to its carbon and alloy content, 4135 / 34CrMo4 responds well to induction hardening:

- Surface heating to austenitizing temperatures followed by rapid quenching

- Achievable surface hardness can reach approx. 50 – 58 HRC, depending on process parameters

- Suitable for localized hardening of gears, camshafts, and bearing seats

After induction hardening, tempering at a moderate temperature is recommended to reduce brittleness of the hardened layer while maintaining high surface hardness.

Nitriding

Certain variants of 34CrMo4 / 4135 can be nitrided to produce a thin, hard surface layer consisting of nitrides. Advantages include:

- High surface hardness with excellent wear resistance

- Minimal distortion due to low process temperatures (commonly 480 – 550 °C)

- Improved fatigue strength, especially for components under cyclic loading

The core hardness before nitriding should be appropriately selected to support the nitrided case, typically by quenching and tempering to a medium hardness before nitriding.

Coatings and Corrosion Protection

Since 4135 / 34CrMo4 does not have high inherent corrosion resistance, protective measures such as painting, phosphating, plating, or modern coating systems are commonly used, depending on application environment. For service involving lubricated contact, proper selection of lubricant and surface roughness is important for wear control.

Corrosion Resistance

4135 / 34CrMo4 is not a stainless steel and has limited corrosion resistance. In standard atmospheric conditions, unprotected surfaces will rust. Key aspects include:

- In indoor dry environments, moderate surface protection (e.g. oil film) can be sufficient

- In outdoor or humid environments, paints, coatings, or plating are typically required

- In aggressive environments (salt spray, chemical exposure), stainless steels or specially coated solutions are often preferred

Preventive measures should be considered at the design stage where corrosion could significantly affect component life or function.

Typical Applications of 4135 / 34CrMo4

4135 / 34CrMo4 is used for a wide variety of medium‑ and high‑strength components in mechanical engineering, automotive, and general industrial applications. It is particularly suitable for parts requiring high strength, good toughness, and reliable fatigue performance.

Automotive and Powertrain Components

- Transmission shafts, input and output shafts, propeller shafts

- Gears, pinions, and synchronizer hubs

- Axles, stub axles, and differential components

- Connecting rods and crankshaft elements in some designs

General Mechanical Engineering and Industrial Uses

- Heavy‑duty shafts for gearboxes, pumps, and compressors

- Pinion shafts and gear wheels in industrial gearboxes

- Couplings, flanges, and various machine elements subjected to dynamic loading

- Bolts, studs, and fasteners requiring higher strength than carbon steels

Oil, Gas, and Pressure‑Related Components

- Drill collars and certain drill string components

- Pressure vessel parts, provided applicable codes are satisfied

- Hydraulic cylinder rods and high‑pressure mechanical tubing

Tooling and Fixtures

- Robust fixture elements and clamping devices

- Mandrels, spindles, and other tooling requiring wear resistance and fatigue strength

Comparison with Related Alloy Steels

4135 / 34CrMo4 is part of a broader family of Cr‑Mo alloy steels. In practice, it is often compared with nearby grades such as 4130, 4140, and 42CrMo4.

Comparison with 4130

- 4130 has lower carbon content (~0.28 – 0.33%), giving better weldability and toughness but lower maximum strength and hardness

- 4135 provides higher attainable strength and wear resistance due to slightly higher carbon

Comparison with 4140 / 42CrMo4

- 4140 / 42CrMo4 typically has higher carbon (~0.38 – 0.45%) and often slightly higher Cr/Mo, enabling even higher strength

- 4135 / 34CrMo4 provides a compromise with somewhat better toughness and weldability than 4140 while still offering high strength

Selection between these steels is based on required strength level, toughness, weldability, and cost‑performance considerations. For many automotive and machinery components, 4135 / 34CrMo4 offers a balanced solution.

Design and Selection Considerations

When specifying 4135 / 34CrMo4, engineers should consider not only the base strength level but the entire lifecycle of the component, including manufacturing, service environment, and maintenance.

Key Considerations

- Required mechanical properties and applicable standards (e.g. EN 10083‑3 or specific OEM specifications)

- Section size and geometry, due to its influence on achievable hardness and microstructure uniformity

- Heat treatment route and its impact on distortion, residual stresses, and dimensional tolerances

- Surface treatment needs for wear, fatigue, or corrosion performance

- Welded vs. integral design, and whether the weldability constraints are acceptable

For highly safety‑critical applications, consideration of steel cleanliness, inclusion control, and quality class (e.g. special bar quality, vacuum degassed material) is often necessary to ensure consistent fatigue and toughness performance.

Typical Problems and Practical Considerations

In practical use of 4135 / 34CrMo4, certain recurring issues are observed if design and process control are insufficient:

- Distortion after quenching and tempering, especially in asymmetric or thin‑walled parts

- Insufficient hardness or soft cores in overly thick sections when hardenability limits are exceeded

- Cracking in welded joints or heat‑affected zones when preheat and hydrogen control are inadequate

- Unexpected fatigue failures due to surface defects, inclusions, or insufficient surface finishing and treatment

Preventing these issues requires coordinated design, heat treatment practice, machining strategy, and quality assurance, including proper testing and inspection routines.